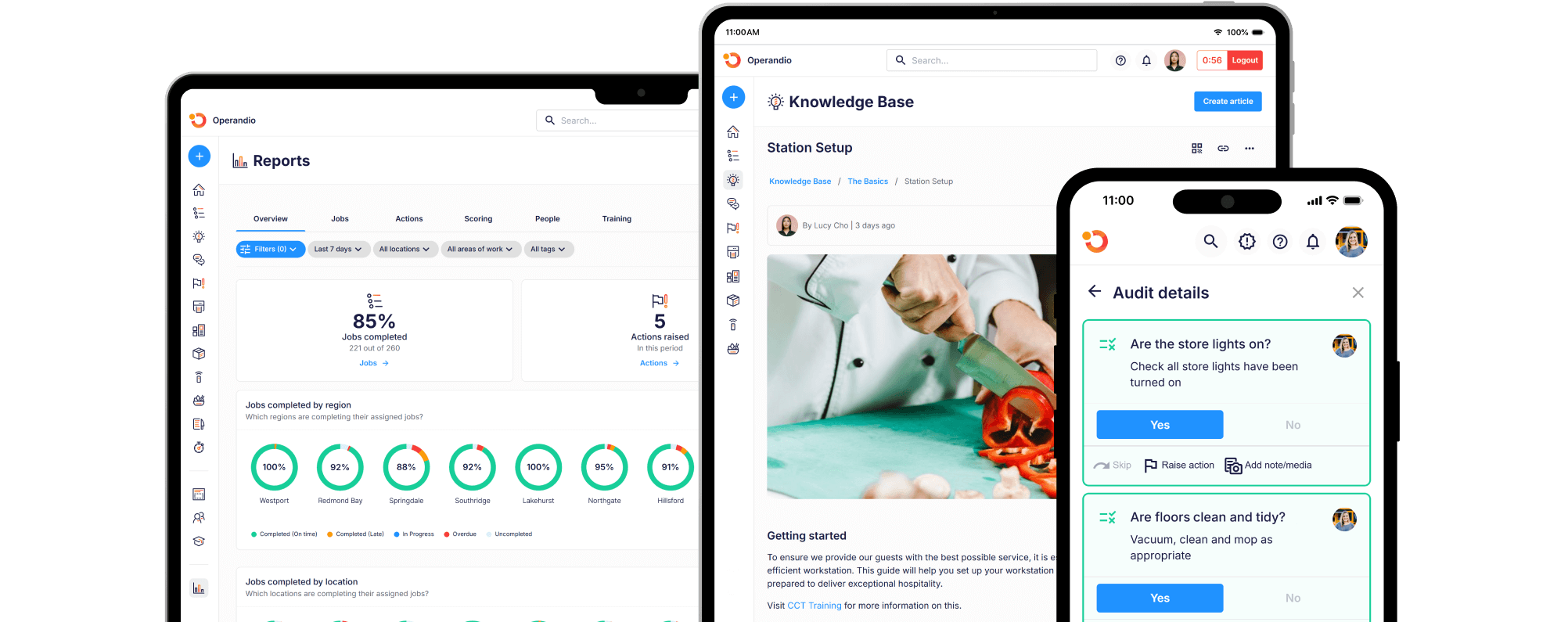

Operandio uses smart wireless IoT sensors to automatically track temperature and humidity across all equipment, including walk-ins, fridges, and freezers. By logging every reading automatically, it eliminates the need for manual paperwork and ensures your data is stored securely for audit-ready reporting.

Trusted by thousands of multi-unit service businesses & franchise groups worldwide

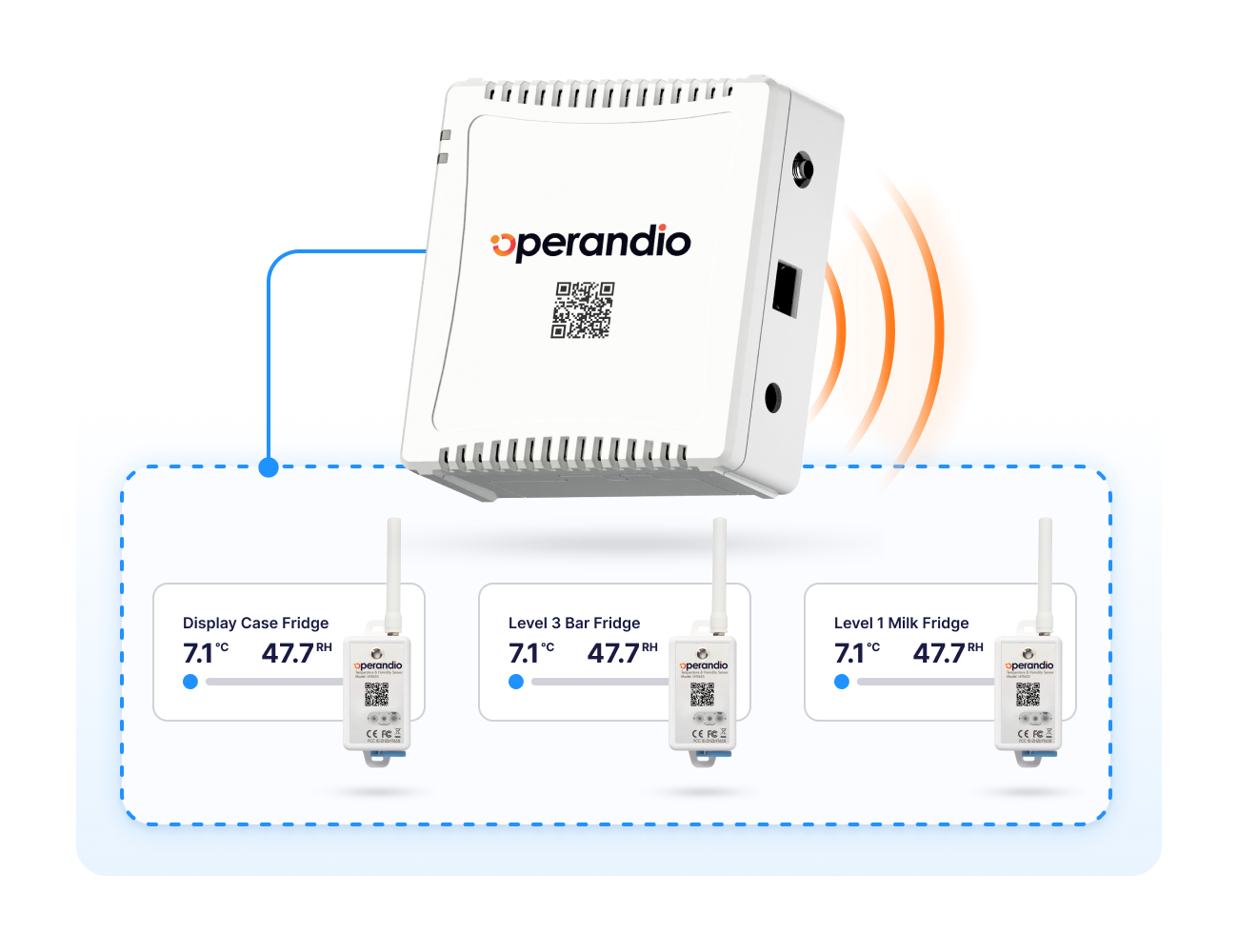

Smart IoT sensors built for every food safety environment

Use best-in-class sensors from trusted manufacturers to monitor walk-ins, fridges, freezers, cold rooms and specialty equipment. Operandio supports a wide range of sensor options, giving you flexibility without locking you into a single vendor.

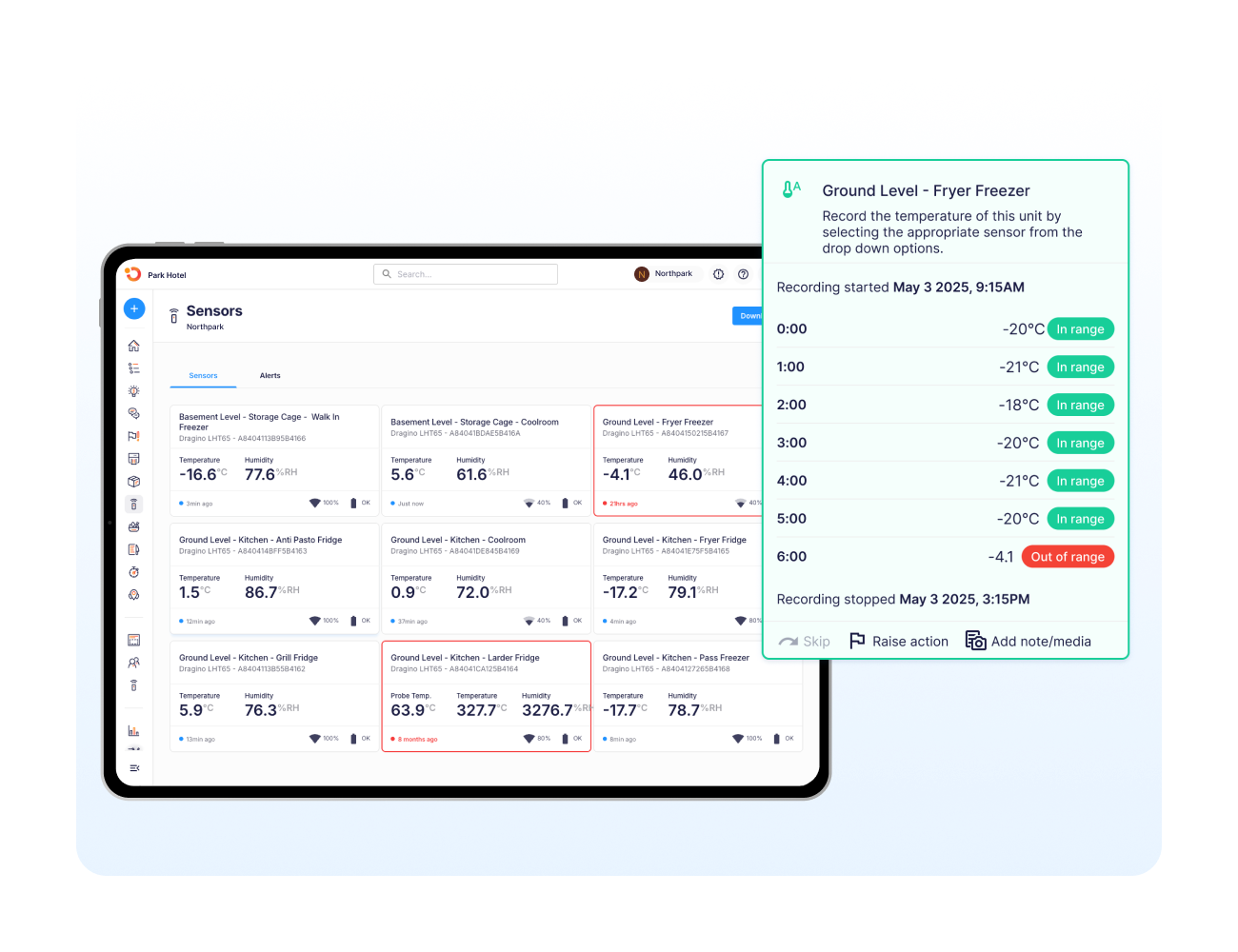

Real-time alerts and automated corrective actions

Get notified instantly by SMS, email or in-app alerts when temperatures move out of range. Automatically trigger corrective actions and escalation workflows so teams respond before food quality is compromised.

Track equipment health, performance and long-term trends

Monitor temperature and humidity patterns over time to identify failing equipment, unstable units or inefficiencies before they become costly issues. Plan repairs and replacements proactively with all historical monitoring data stored securely in one place for easy compliance management.

Automated logging for effortless compliance

Eliminate manual checks and paperwork. Every temperature reading is logged automatically, stored securely and available in exportable audit-ready reports.

Multi-location visibility for managers & operators

View performance across every site in real time, compare compliance levels and quickly pinpoint locations that need attention. Reduce labour costs by eliminating manual checks and centralising oversight so managers can monitor food safety standards across the entire network from anywhere.

Automated Temperature Monitoring is just the beginning

Explore the full suite of Food Safety solutions available in one mobile-first platform.

You’re in good company

Companies just like yours are using Operandio to achieve staff accountability, safety, compliance and consistent business processes across all their locations.

Frequently asked questions

The system provides real-time alerts via SMS, email, or in-app notifications the moment conditions fluctuate. It can also automatically trigger corrective actions and escalation workflows, ensuring your team responds quickly to protect food quality before spoilage occurs.

Operandio is designed for flexibility. It supports a wide range of best-in-class sensors from various trusted manufacturers. This allows you to monitor specialty equipment and standard units without being locked into a single hardware vendor.

Every degree maintained above the required safe temperature can increase energy use by 5–10%. Operandio’s AI insights identify inefficient equipment and unstable trends, helping you reduce energy waste and extend the lifespan of your assets.

Yes. Operandio provides multi-location visibility, allowing managers to monitor food safety standards across an entire network from anywhere. You can compare compliance levels between sites, pinpoint locations that need attention, and reduce labor costs by centralizing oversight.