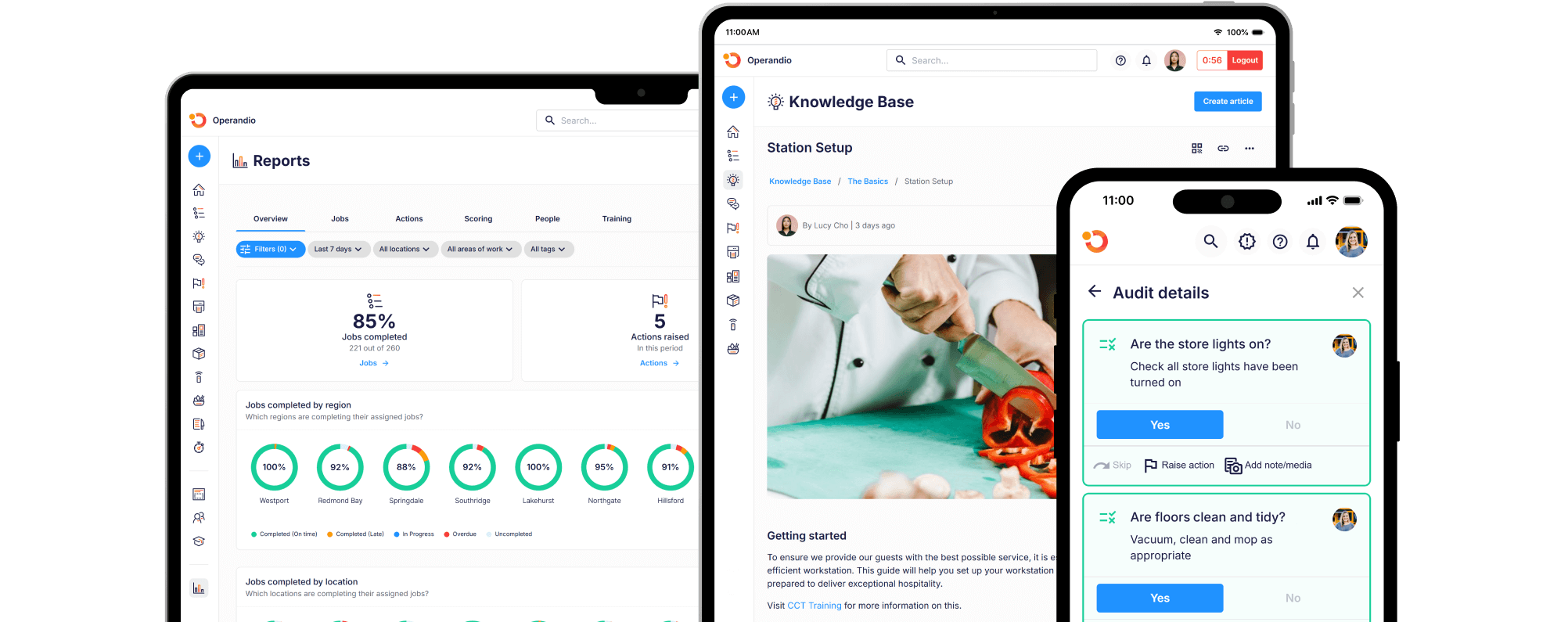

You can create a complete registry of all equipment and infrastructure to monitor condition across every site. The system allows you to track specific asset details, maintenance history, and performance over time to ensure operations run smoothly.

Trusted by thousands of multi-unit service businesses & franchise groups worldwide

Track assets and monitor condition across every site

Create a complete registry of your equipment and infrastructure. Track asset details, maintenance history, inspections and performance over time to keep operations running smoothly.

Preventive maintenance schedules and inspections

Reduce breakdowns with recurring maintenance schedules. Set inspections, tasks and servicing intervals so assets are checked on time, every time, across all locations.

Smart work orders for fast, structured repairs

Create work orders in seconds when equipment fails or inspections uncover issues. Assign tasks, capture photos, track status and close out repairs with full transparency.

Parts and inventory management

Track spare parts, consumables and stock levels. Link parts to specific work orders, monitor usage and avoid equipment downtime caused by missing components.

Automated corrective actions and maintenance workflows

When issues are identified, tasks and work orders are automatically created. Assign responsibility, set deadlines and track completion until equipment is fully operational.

Asset performance insights and maintenance reporting

Analyse asset reliability, recurring issues, maintenance trends and repair times. Use insights to extend asset life, reduce failures and make smarter replacement decisions.

View the full suite of powerful Asset Management features

Explore our full suite of Asset Management tools.

You’re in good company

Companies just like yours are using Operandio to achieve staff accountability, safety, compliance and consistent business processes across all their locations.

Frequently asked questions

To reduce breakdowns, you can set up preventive maintenance schedules with recurring inspections and servicing intervals. This ensures that assets are checked on time, every time, regardless of the location.

When failure occurs, you can generate smart work orders in seconds to capture photos, assign tasks, and track repair status with full transparency. Additionally, issues identified during inspections can trigger automated workflows that create work orders and set deadlines until the asset is operational.

Yes, the platform includes parts and inventory management to track spare parts and consumables. You can link these parts directly to specific work orders and monitor usage to avoid downtime caused by missing components.

The system provides asset performance insights that allow you to analyze reliability, repair times, and recurring maintenance trends. These reports help you make smarter replacement decisions and identify ways to extend the life of your assets.

Every asset, task and action is tracked, visible and under control.