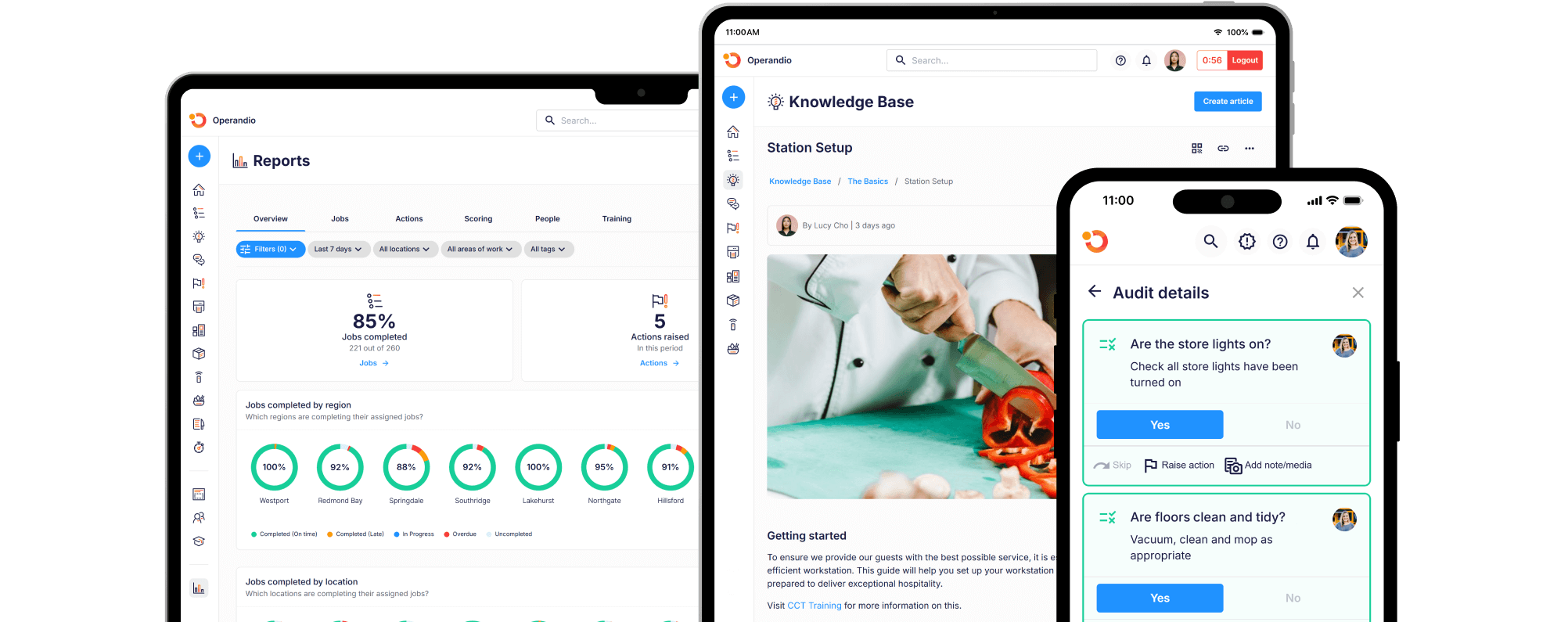

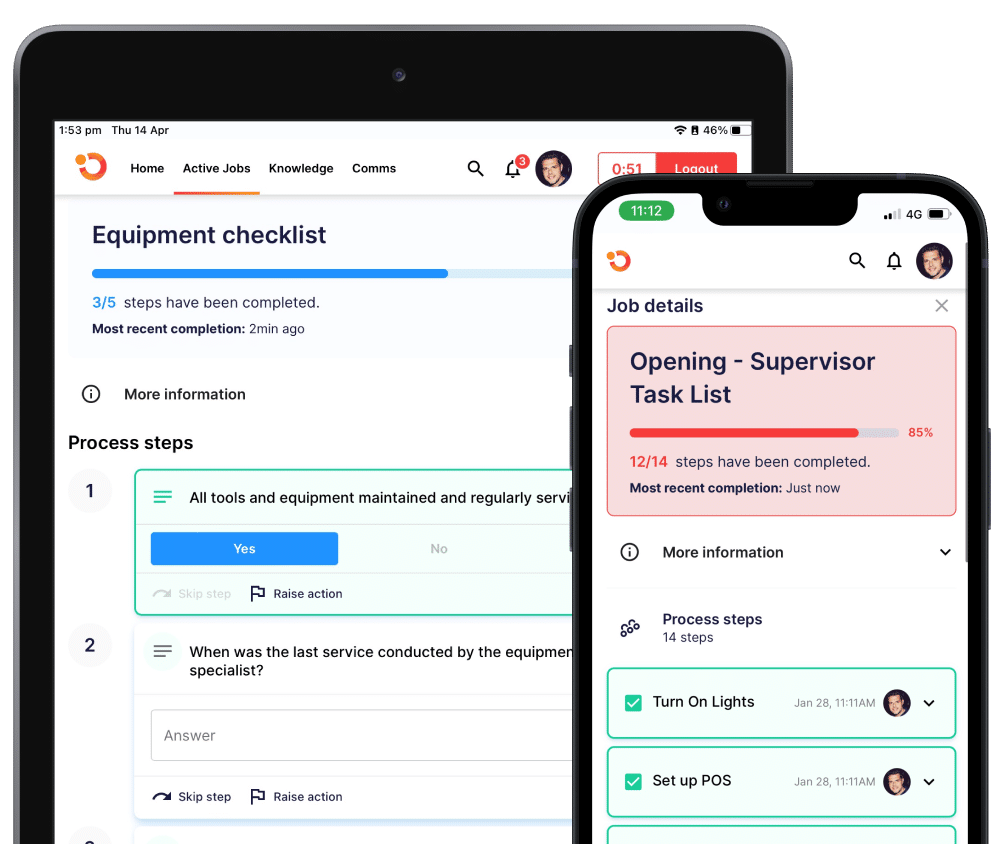

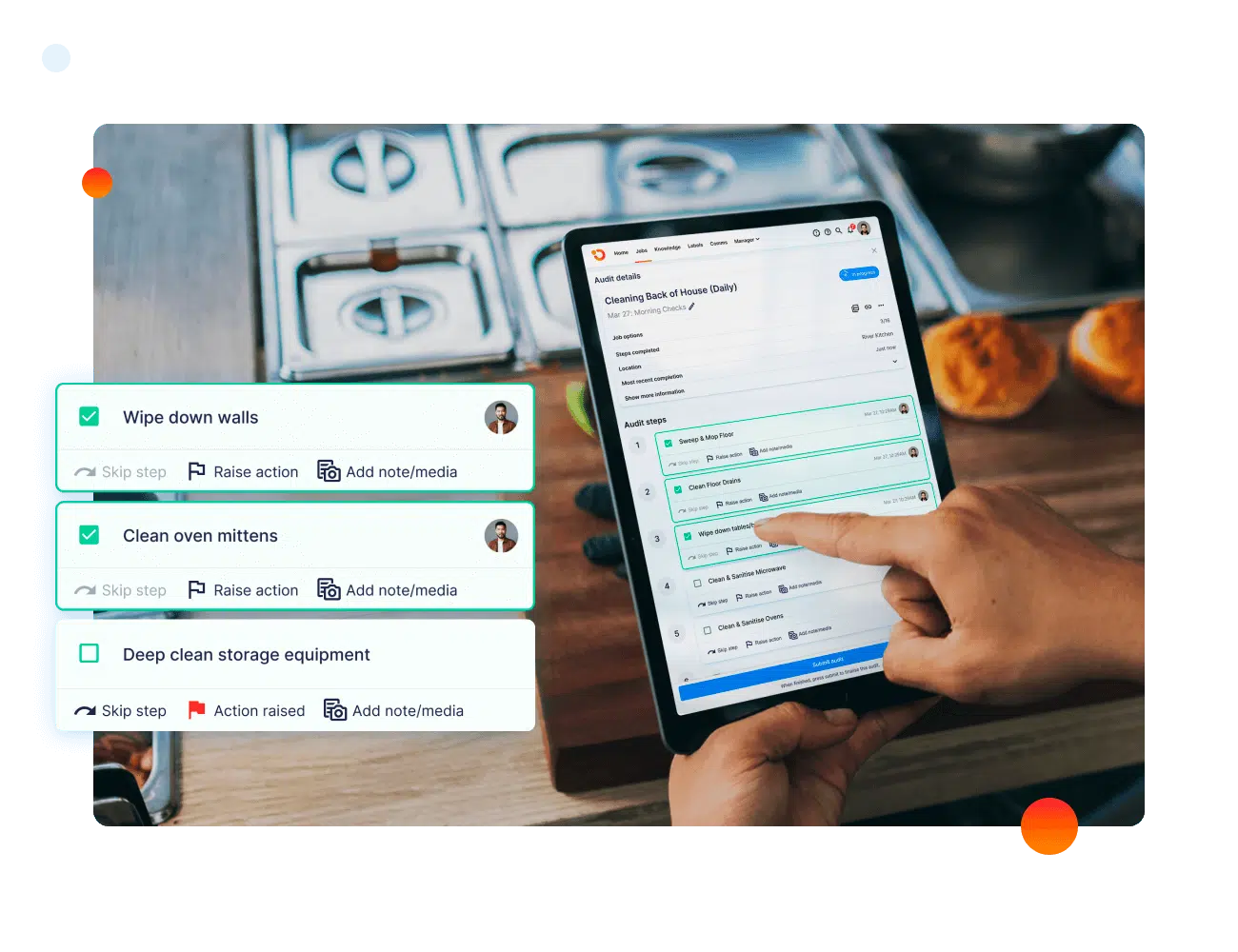

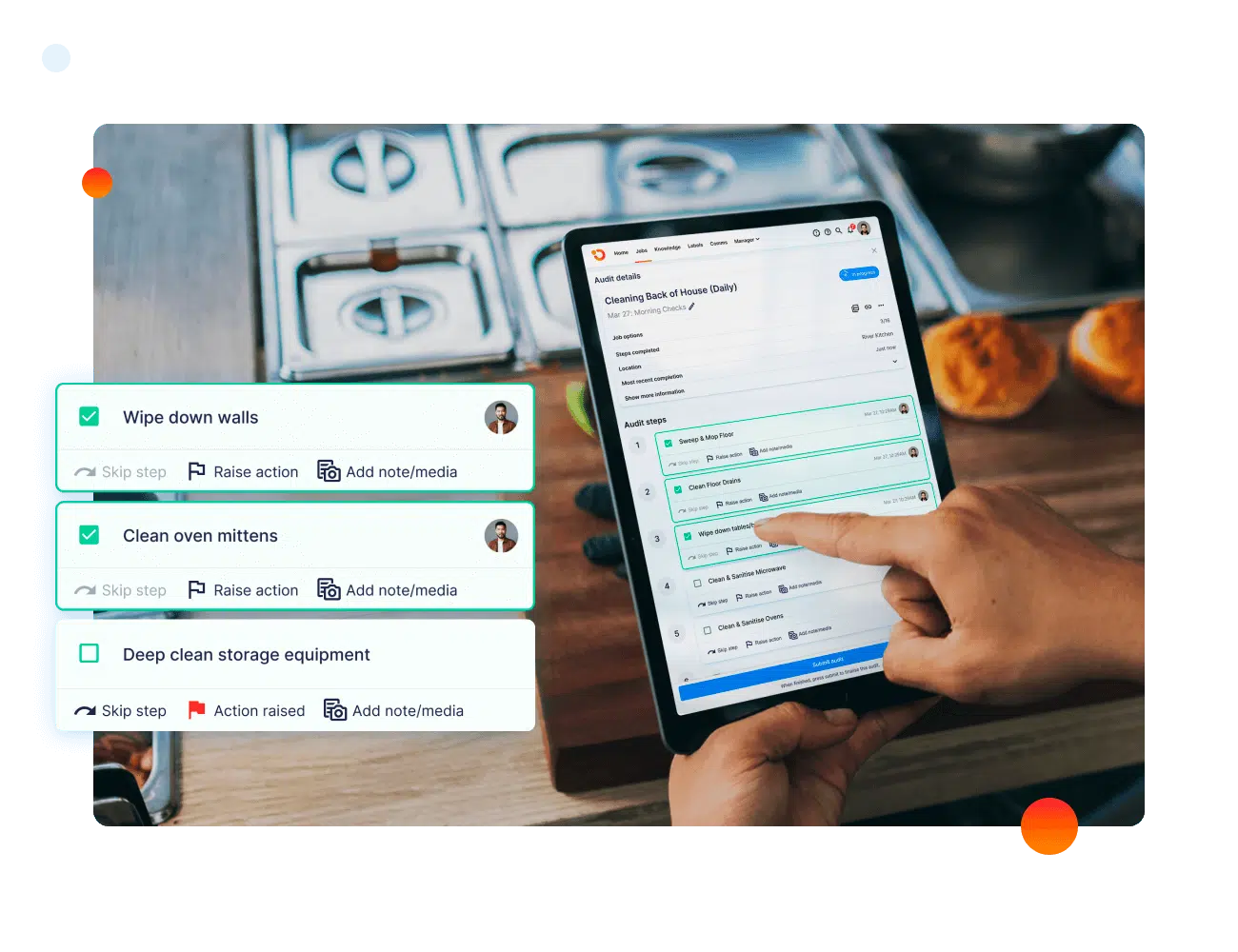

You can replace manual paper checks with structured digital workflows for line checks, sanitation routines, cooling logs,and prep checks. These digital processes provide step-by-step guidance to ensure frontline teams follow compliant procedures at every location.

Digitize HACCP and food safety processes

Replace paper logs and manual checks with structured digital workflows for prep checks, line checks, sanitation routines, cooling logs, storage checks and more. Ensure every team follows compliant procedures with step-by-step guidance designed for frontline operators.

Automated temperature monitoring with AI insights

Protect food quality and reduce spoilage with hardware-agnostic sensors that continuously monitor equipment across your network. Receive instant alerts, automatically trigger corrective actions and use AI insights to reduce energy usage and extend equipment life.

Accurate labeling and consistent food rotation

Standardize prep and expiry labels across your entire network using the printers you already own. Improve rotation accuracy, reduce waste and maintain compliance with automated templates controlled centrally at HQ.

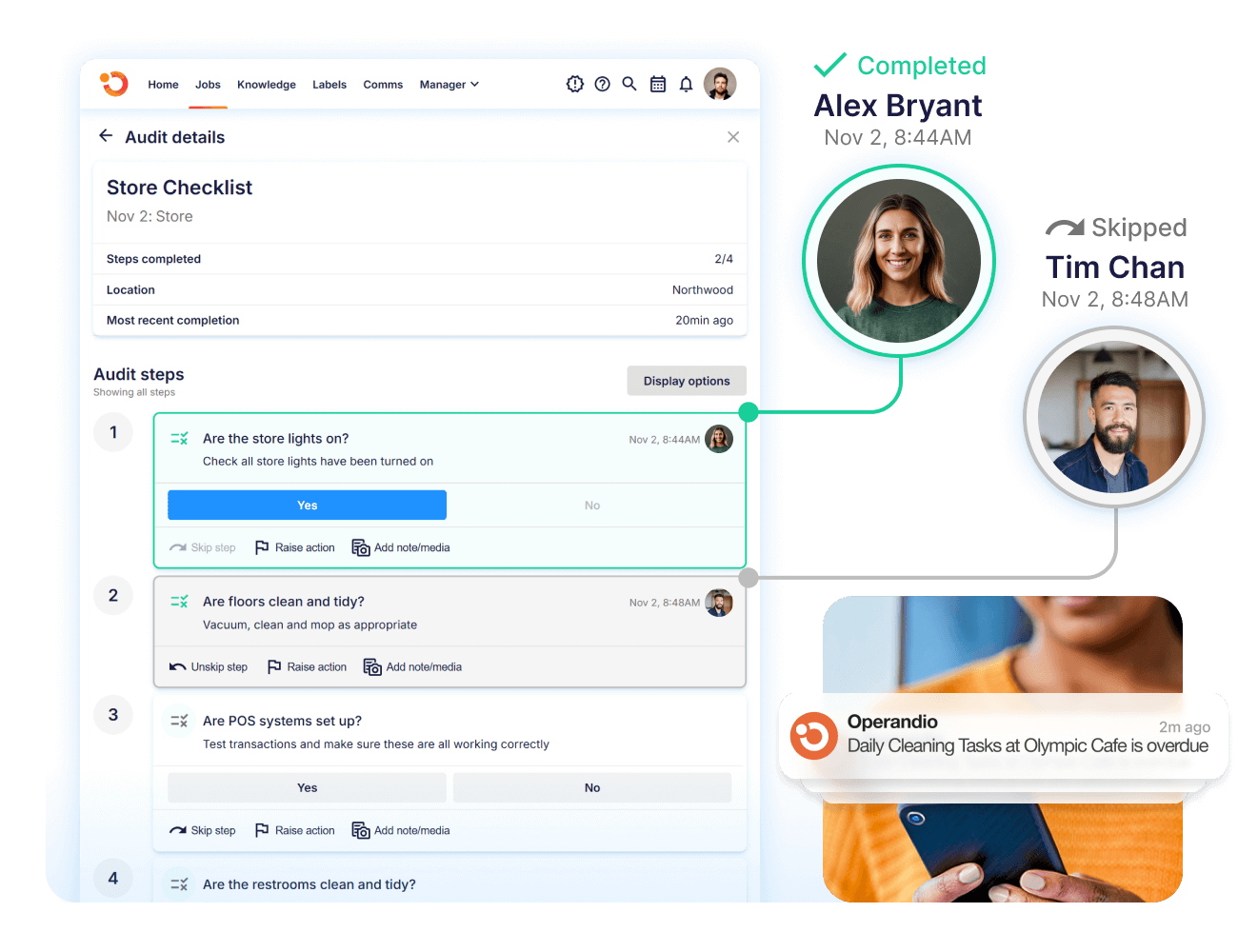

Corrective actions that close the loop on food safety issues

Automatically escalate issues triggered by failed checks, out-of-range temperature readings or non-compliant labeling. Assign tasks, track completion and ensure every problem is resolved with full accountability across every location.

Audit-ready compliance records and traceability

Automatically log every food safety action, including checks, readings, labels and corrective actions. Prepare for inspections quickly with exportable reports and complete traceability across brands, regions or franchise groups.

HACCP-aligned processes and regulatory compliance built in

Ensure every location meets U.S., Australian, UK and international food safety standards with workflows aligned to HACCP principles, FSMA requirements, FDA temperature controls and local health regulations. Maintain audit-ready logs, critical control point verification, corrective actions and full traceability – all digitally recorded and centrally managed.

Designed for every type of food business

Support consistent food safety across restaurants, QSR, cafes, hotels, convenience retail, aged care, healthcare, education, production facilities and distribution. Maintain standards regardless of industry, region or scale.

Discover the full suite of Digital Food Safety features

Every check, reading and action is recorded, traceable and audit-ready, giving your teams the tools to operate safely and consistently – whether you run 5 locations or 5,000.

You’re in good company

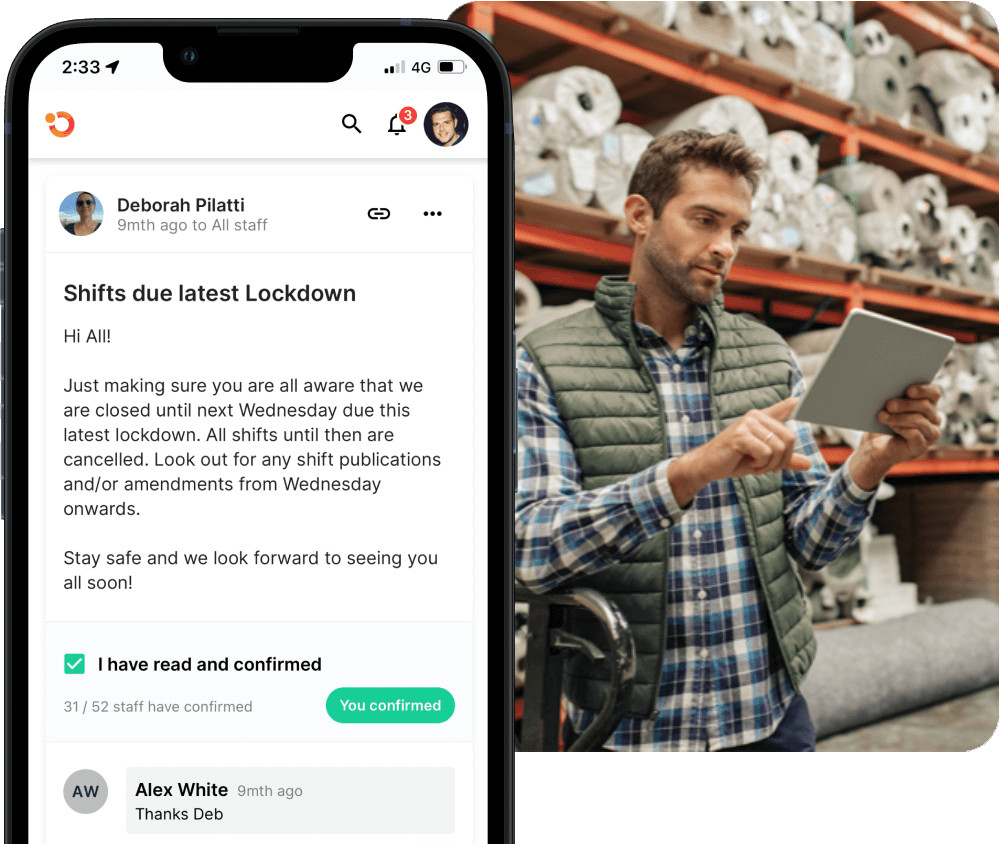

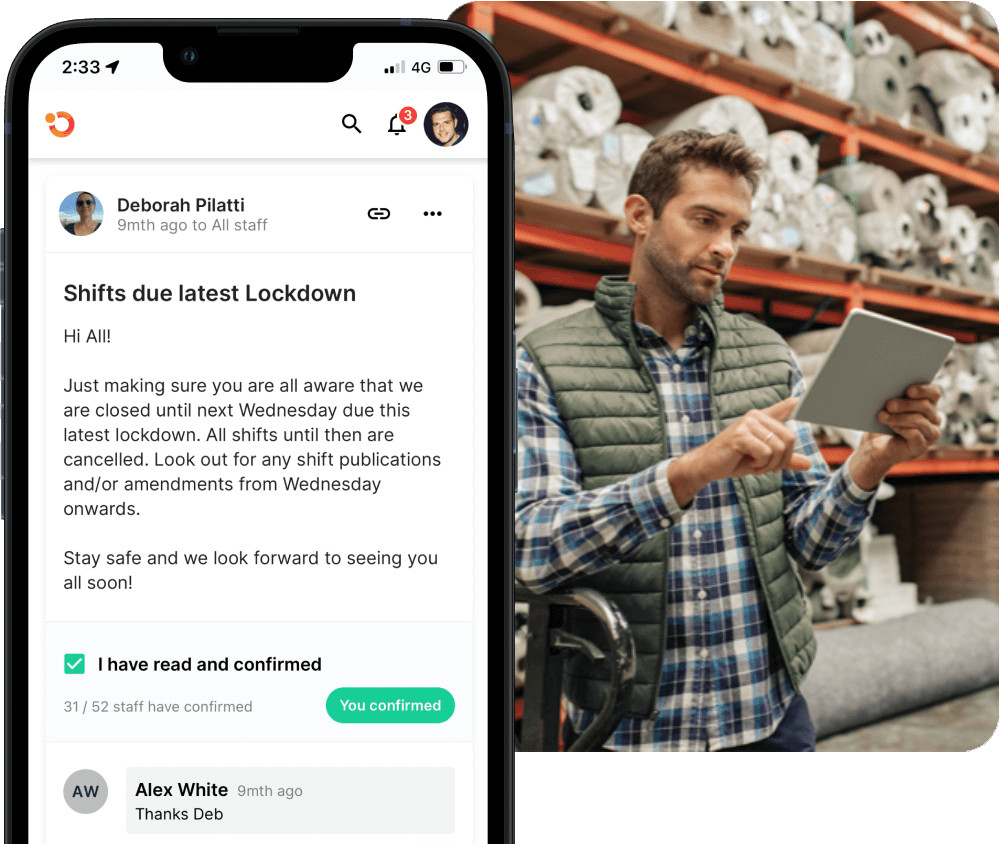

Companies just like yours are using Operandio to achieve staff accountability, safety, compliance and consistent business processes across all their locations.

Frequently asked questions

The platform uses hardware-agnostic sensors to continuously monitor equipment and provide automated temperature alerts. When issues occur, the system automatically triggers corrective actions and uses AI insights to help reduce energy usage and extend the life of your equipment.

Yes, you can use automated templates controlled centrally from HQ to standardize prep and expiry labels across your network using your existing printers. This helps improve rotation accuracy, reduces food waste, and ensures consistent compliance at every site.

The system automatically generates and escalates corrective actions whenever a failed check or non-compliant reading is detected. Managers can assign tasks and track completion to ensure every issue is resolved with full accountability across every location.

Every food safety action, including labels and checks, is automatically logged to create audit-ready compliance records and complete traceability. The platform is built to align with international standards such as HACCP principles, FSMA requirements, and FDA controls, providing exportable reports for quick inspection preparation.

All process guides, training materials, and compliance documents are stored in a unified, centralized library. This ensures every location has quick access to the same approved standards and provides version control for audit-ready documentation.