HACCP Plan: Key Steps, Templates & Examples (2026 Guide)

Key Takeaways

- A HACCP plan is a systematic approach to identifying and controlling food safety hazards at critical points in your production process, from receiving to service.

- The 7 HACCP principles provide a framework for preventing foodborne illness: conduct hazard analysis, identify critical control points, establish limits, monitor CCPs, create corrective actions, verify the system, and maintain documentation.

- Multi-unit restaurants face unique HACCP challenges including consistency across locations, high staff turnover, and compliance tracking.

- Common mistakes like incomplete logs, inconsistent monitoring, and paper-based systems create compliance gaps that can lead to health violations and brand reputation damage.

Managing food safety across multiple restaurant locations means dealing with different staff, varying experience levels, and the constant pressure to maintain consistency. A HACCP plan helps you systematically identify and control food safety hazards before they become problems.

In this guide, you’ll learn what a HACCP plan is, the 7 core principles, step-by-step instructions for creating your plan, and common mistakes multi-unit operators make. We’ll also show you how to implement HACCP across multiple sites without drowning in paperwork.

What is HACCP?

If you’re unfamiliar with the specifics of a HACCP plan, don’t worry. We can explain. A HACCP plan is an organised approach, like a food safety checklist, that helps identify, evaluate, and control hazards that can cause food safety issues. It aims to prevent, eliminate, or reduce risk to acceptable levels.

HACCP was developed in the 1960s by the Pillsbury Company, the National Aeronautics and Space Administration (NASA), and the U.S. Army Laboratories. They were looking for a way to guarantee food safety for astronauts on space missions. They wanted to prevent food-borne illnesses from occurring in unideal locations.

In other words, they wanted to prevent a “one small step for man, one giant leap to the restroom” scenario. The system proved to be a hit amongst those involved. It was such a success that other industries took note, with the food industry and regulatory agencies worldwide taking a shine to it.

In hospitality, HACCP plans can help guarantee a venue’s food is safe for consumption. It can be prepared for a restaurant kitchen, served in a hotel buffet, or delivered by a catering service. This precautionary approach identifies potential hazards and implements control measures to minimize or eliminate them.

Why HACCP is Important for Multi-Unit Restaurants

Oftentimes, running 10, 20, or 50 business locations introduces exponential complexity.

Each site has different staff with varying experience levels, skills, and exposure. A lack of training may cause high turnover due to inconsistent customer experience.

For example, A single food safety incident at one location can damage your entire brand reputation. A health department violation at your Chicago location appears in Google searches alongside your Dallas and Phoenix restaurants.

Hence, the stakes are higher for multi-unit operators. Because Customers don’t distinguish between franchise operations, they see one brand.

This is why implementing HACCP audits across all locations becomes critical.

You need unified checklists, consistent monitoring procedures, and real-time visibility into compliance at every site.

Kitchen compliance can’t rely on paper logs that sit in binders for weeks before anyone reviews them. Digital systems ensure your HACCP plan actually works in practice, not just in theory.

The 7 HACCP Principles

The HACCP system is built on seven fundamental principles that guide how you identify and control food safety hazards.

These principles work together to create a comprehensive food safety management system that protects customers and your business.

Principle #1: Conduct a Hazard Analysis

Identify potential biological, chemical, and physical hazards in your food production process.

For a burger restaurant, biological hazards include bacteria like E. coli in ground beef, chemical hazards might be cleaning solution residue on prep surfaces, and physical hazards could be metal fragments from equipment.

Principle #2: Determine Critical Control Points (CCPs)

These are specific steps where you can apply control measures to prevent or eliminate hazards. Cooking is a CCP for that burger; it’s your kill step for bacteria.

Cold storage temperature is another CCP. Missing these control points means hazards reach customers.

Principle #3: Establish Critical Limits

Set measurable limits at each CCP. That burger must reach 155°F internal temperature. Your walk-in cooler must stay below 41°F.

These aren’t suggestions; they’re science-based requirements for safety. Food safety monitoring means tracking these exact numbers, not guessing.

Principle #4: Establish Monitoring Procedures

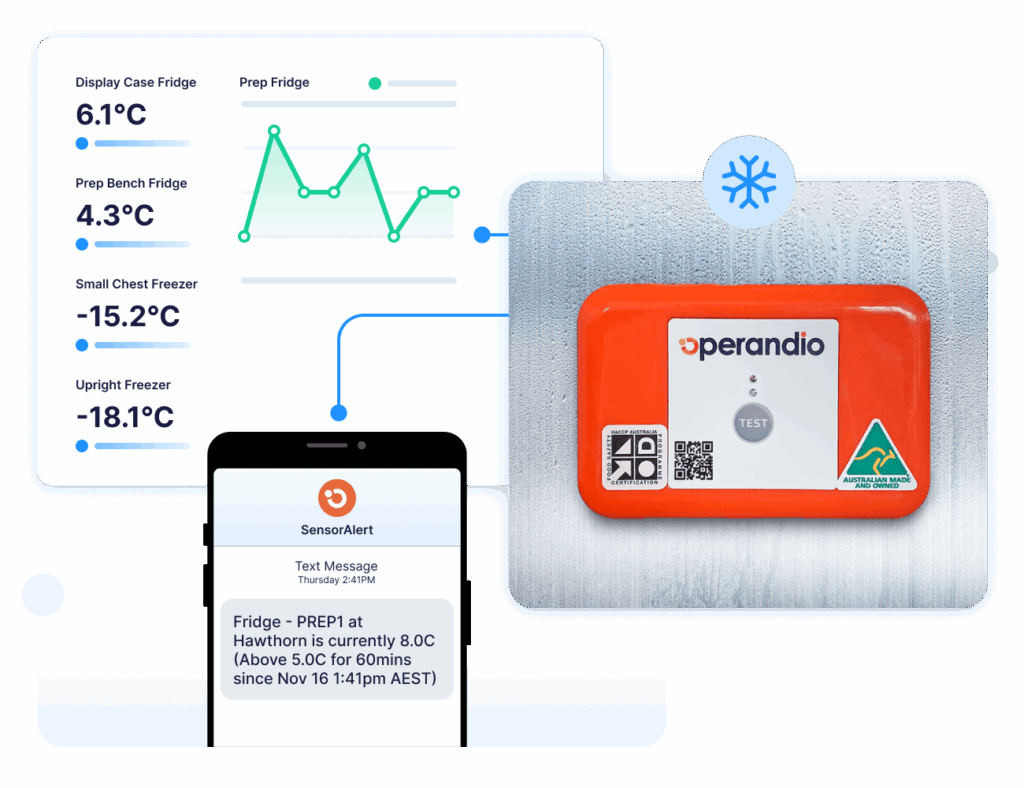

Define how you’ll check CCPs. For cooking temps, you might require staff to temp-check every burger batch and log results. For cooler temps, you could use digital sensors that alert managers when temperatures drift.

The key is consistency; monitoring must happen at every location, every shift, without exception.

Principle #5: Establish Corrective Actions

When monitoring shows a deviation, you need predetermined responses. If a burger comes off the grill at 145°F, the corrective action is simple: cook it longer and re-check. If a cooler hits 45°F, you move product to backup storage and call maintenance immediately.

These decisions shouldn’t require a manager’s judgment calls at 2 AM.

Principle #6: Establish Verification Procedures

Regularly confirm your HACCP system works as intended. This includes calibrating thermometers weekly, reviewing temperature logs, conducting internal audits, and testing final products. Food safety certificate compliance often requires documentation of these verification activities.

Principle #7: Establish Record-Keeping

Document everything: hazard analysis, CCP monitoring logs, corrective actions, verification activities, and staff training.

For multi-unit operators, centralized digital records make audits easier and help you spot patterns across locations. Restaurant food safety software can automate much of this documentation burden.

How to Create a HACCP Plan: Step-by-Step

Creating a HACCP plan requires systematic thinking about your entire food production process. For multi-unit restaurants, the challenge is building a plan that works consistently across all locations while allowing for site-specific adjustments.

Step 1: Assemble Your HACCP Team

Pull together people who understand your operation: kitchen managers, executive chefs, operations directors, and ideally someone with food safety certification. For multi-unit operations, include representatives from different regions who can speak to local challenges and requirements.

Step 2: Describe Your Menu and Processes

Document every menu item and how it’s prepared. Map the flow from receiving ingredients through storage, prep, cooking, holding, and service. The more detailed, the better. A pizza restaurant would document dough prep, sauce production, topping storage, oven cooking, and delivery/holding procedures.

Step 3: Identify Hazards

Walk through each process step and identify what could go wrong. Raw chicken stored above vegetables? Cross-contamination risk. Prep surfaces not sanitized between tasks? Bacteria transfer.

This is where building a strong food safety culture matters; your team needs to think critically about risks.

Step 4: Determine Critical Control Points

Which steps are make-or-break for safety? Cooking is almost always a CCP.

Cooling procedures for large batches are CCPs. Cold storage is a CCP. Hand washing, while important, usually isn’t a CCP; it’s a prerequisite program.

Step 5: Establish Critical Limits for Each CCP

Set specific, measurable targets. Chicken breast: 165°F minimum internal temp. Hot holding: 135°F or above. Cooling: 135°F to 70°F within 2 hours, then 70°F to 41°F within 4 more hours. These limits come from food code requirements and FDA guidelines.

Step 6: Establish Monitoring Procedures

Define who checks CCPs, how often, and how they record results. “Check cooler temps every 4 hours and log on the daily checklist” is specific. “Monitor coolers regularly” is useless. For chains, free and paid HACCP software solutions can ensure consistent monitoring protocols.

Step 7: Develop Corrective Actions

Create if-then responses for every CCP. If hot holding drops below 135°F, reheat to 165°F and hold at 135°F or discard if held under temp for more than 2 hours. Clear corrective actions eliminate guesswork during busy service.

Step 8: Establish Verification

Schedule regular reviews: calibrate thermometers weekly, audit logs monthly, and conduct internal HACCP audits quarterly. Food industry compliance management requires proof that your system works over time, not just during health inspections.

Step 9: Document Everything

Create your HACCP plan document with all hazard analyses, CCPs, limits, monitoring procedures, corrective actions, and verification schedules. Then maintain ongoing records of daily monitoring, corrective actions taken, and verification activities.

A HACCP Plan Example

Let’s walk you through how HACCP principles apply in practice. This example shows the systematic approach to identifying and controlling hazards throughout your food production process.

1. Conduct a Hazard Analysis

Your first step involves identifying and evaluating potential hazards associated with food production.

Hazards can be biological (e.g., bacteria, viruses), chemical (e.g., pesticides, cleaning agents), or physical (e.g., glass, metal). A thorough hazard analysis helps determine which risks related to food production are significant and must be addressed through the HACCP plan.

2. Identify Critical Control Points (CCPs)

CCPs are specific points in the food production process where control measures can be applied to prevent, eliminate, or reduce hazards to acceptable levels. These points are crucial for ensuring food safety. This step involves classifying cooking, cooling, and storage temperatures and procedures for preventing cross-contamination, like kitchen hygiene and equipment sanitation.

3. Establish Critical Limits

Don’t be alarmed; this isn’t the tagline of a ’90s action film. Instead, critical limits are the maximum or minimum values that must be met at each CCP. These limits are based on regulatory requirements, industry standards, and scientific evidence. For example, the critical limit for cooking poultry is a minimum internal temperature of 165°F. Every poultry-based dish must meet this temperature every time to guarantee safe consumption.

4. Monitor CCPs

A carry-over from the previous steps, this involves regularly checking and recording the CCP to make sure the critical limits are being met. This can be done through visual observation, temperature measurements, and testing.

Monitoring the CCPs helps identify deviations from critical limits — whether it’s a cooking point or a walk-in cooler temperature — and safeguards that your control measures are effective.

5. Establish Corrective Actions

The reality is that things will go wrong, and systems can falter. Here is where you can help lessen these faults. Corrective actions are steps taken when a deviation from a critical limit occurs.

These are in place to prevent unsafe food from reaching patrons. Corrective actions may include re-cooking, discarding the problematic food, or adjusting the process to bring it back into control.

6. Verify the HACCP System

You need to make sure your HACCP plan is working as intended. This can be done through internal and external audits, reviews, and inspections.

Verification ensures the HACCP plan effectively controls hazards and maintains food safety. The last thing you want is to have an ineffective system in place.

7. Record-Keeping and Documentation

Record-keeping and documentation are the crucial final steps for maintaining a HACCP plan. Documentation provides evidence that the HACCP plan is being implemented and maintained, which could be helpful during a regulatory audit or inspection.

This includes keeping records of everything mentioned above and employee training.

Record-keeping and documentation can be challenging, so we’ve developed digital-based checklists to simplify the process. They’re much more efficient than grubby paper checklists.

The Benefits of Implementing a HACCP Plan

Beyond regulatory compliance, a well-executed HACCP system creates tangible operational and financial benefits for multi-unit restaurants.

Improved Food Safety and Reduced Risk of Foodborne Illnesses

Implementing HACCP helps reduce the risk of foodborne illnesses. By establishing CCPs and critical limits and monitoring them regularly, HACCP guarantees your food is safe for consumption. It’s a handy tool to add to your overall food safety compliance strategy.

Compliance with Regulatory Requirements

Depending on your location, the local authority may require you to have a HACCP plan. HACCP is part of a venue’s compliance process, thus reducing the risk of fines, penalties, and legal issues.

Considering it is a recognised and accepted food safety management system, it could become mandatory across the country in a matter of years.

Enhanced Reputation and Customer Trust

Within hospitality, word-of-mouth and reputation amongst patrons are vital.

Having a HACCP plan in place shows a wholehearted dedication to preserving food safety for customers.

This can lead to a steady supply of regulars, the backbone of a successful venue.

Cost Savings

As the old saying goes, waste not, want not. Through waste reduction and improved efficiency, HACCP helps businesses find and fix problems in the food production process.

It also reduces the risk of foodborne illnesses, which avoids the costs of recalls, lawsuits, and a bad reputation. Over time, the effort you put into developing a HACCP system can pay for itself.

Common HACCP Mistakes and How to Avoid Them

Even with good intentions, multi-unit restaurants often stumble on HACCP implementation. Here are the mistakes that create compliance gaps and how to fix them.

Mistake #1: Incomplete or Inconsistent Logs

Staff skip temperature checks during rush periods, or logs show suspiciously perfect readings (every reading exactly 40°F for a month?).

This happens when monitoring feels like busywork rather than actual safety practice. Digital systems with automated sensors and time-stamped entries eliminate this problem — you can’t fake data that’s captured automatically.

Mistake #2: Using Paper-Based Systems

Paper logs sit in binders for weeks before anyone reviews them. By the time you notice a pattern of temperature violations, you’ve already served potentially unsafe food.

Fragmented systems are costing multi-unit franchises millions through inefficiency and compliance failures.

Mistake #3: Failing to Update HACCP Plans

Any change to your menu, equipment, or kitchen layout should trigger a HACCP plan review.

If you replace an oven with a combi-oven, your cooking times and temperature limits shift, so your critical limits need updates.

Revisit your HACCP plan after each operational change, and complete a full review at least annually.

Mistake #4: Poor Staff Training

New hires receive minimal food safety training, or training is inconsistent across locations. HACCP only works when every team member understands why critical limits matter and how to respond to deviations.

But a standard training programs ensure consistency, especially when staff transfer between your locations.

Mistake #5: No Verification System

You monitor CCPs and keep logs, but nobody verifies that the system actually works.

Without regular verification through calibration checks, log reviews, and internal audits, your HACCP plan becomes paperwork theater rather than actual safety.

Did You Know? Multi-unit operators using digital HACCP systems report 40% fewer health inspection violations compared to those using paper logs. Real-time monitoring and automatic alerts catch problems before they become violations.

Implementing restaurant standards across all locations requires more than good intentions; it requires systems that make compliance the easy choice.

Bring HACCP, Food Safety, and Daily Tasks Into One System With Operandio

Running a HACCP program across 10, 20, or 50 locations becomes messy fast when each site uses its own logs, its own reporting style, and its own mix of tools. Even when teams mean well, the inconsistency creates risk.

Operandio removes that friction. It brings your HACCP checks, food safety records, and daily tasks into one digital system that works the same way everywhere. Teams follow the same steps. Managers see the same data. Nothing gets lost in paper folders or scattered files.

With real-time temperature monitoring, automated alerts, and centralized reporting, you know precisely where each location stands at any moment. You spend less time chasing documentation and more time running a safe, reliable operation.

Book your free demo right now and see how digital HACCP transforms your food safety program.