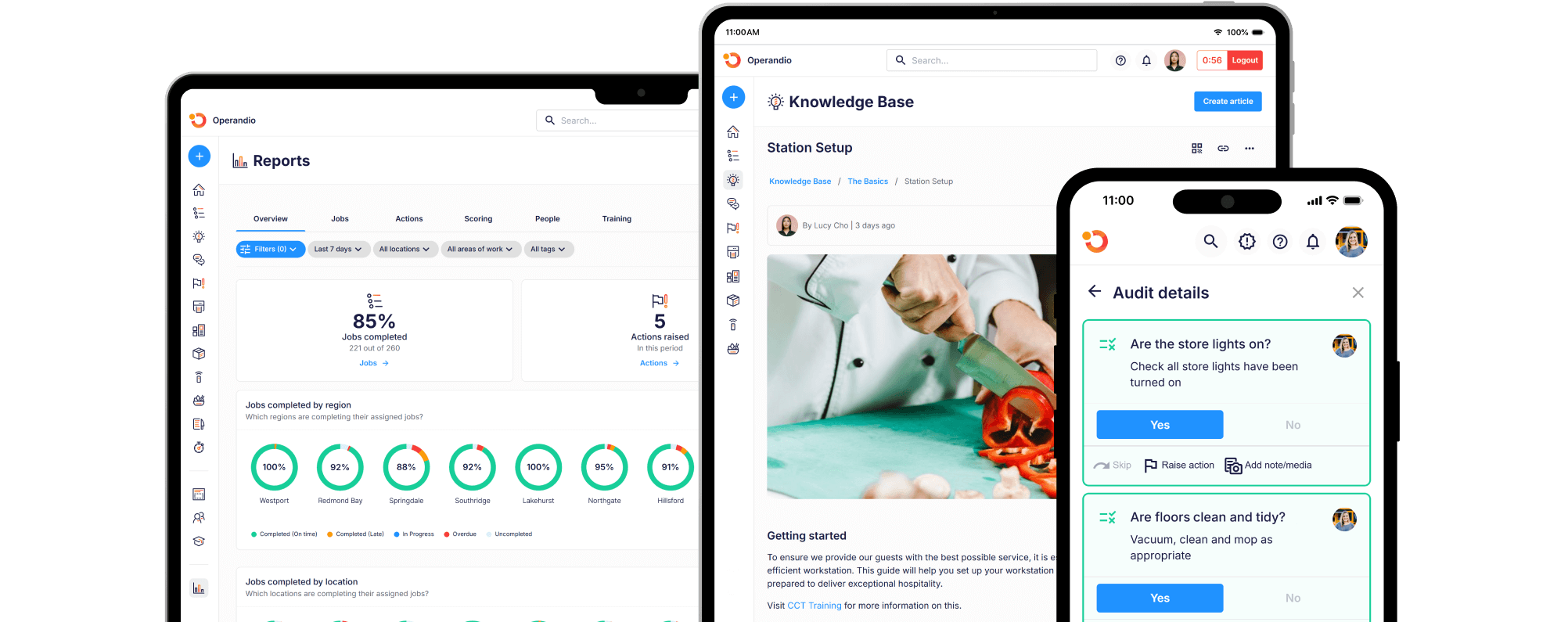

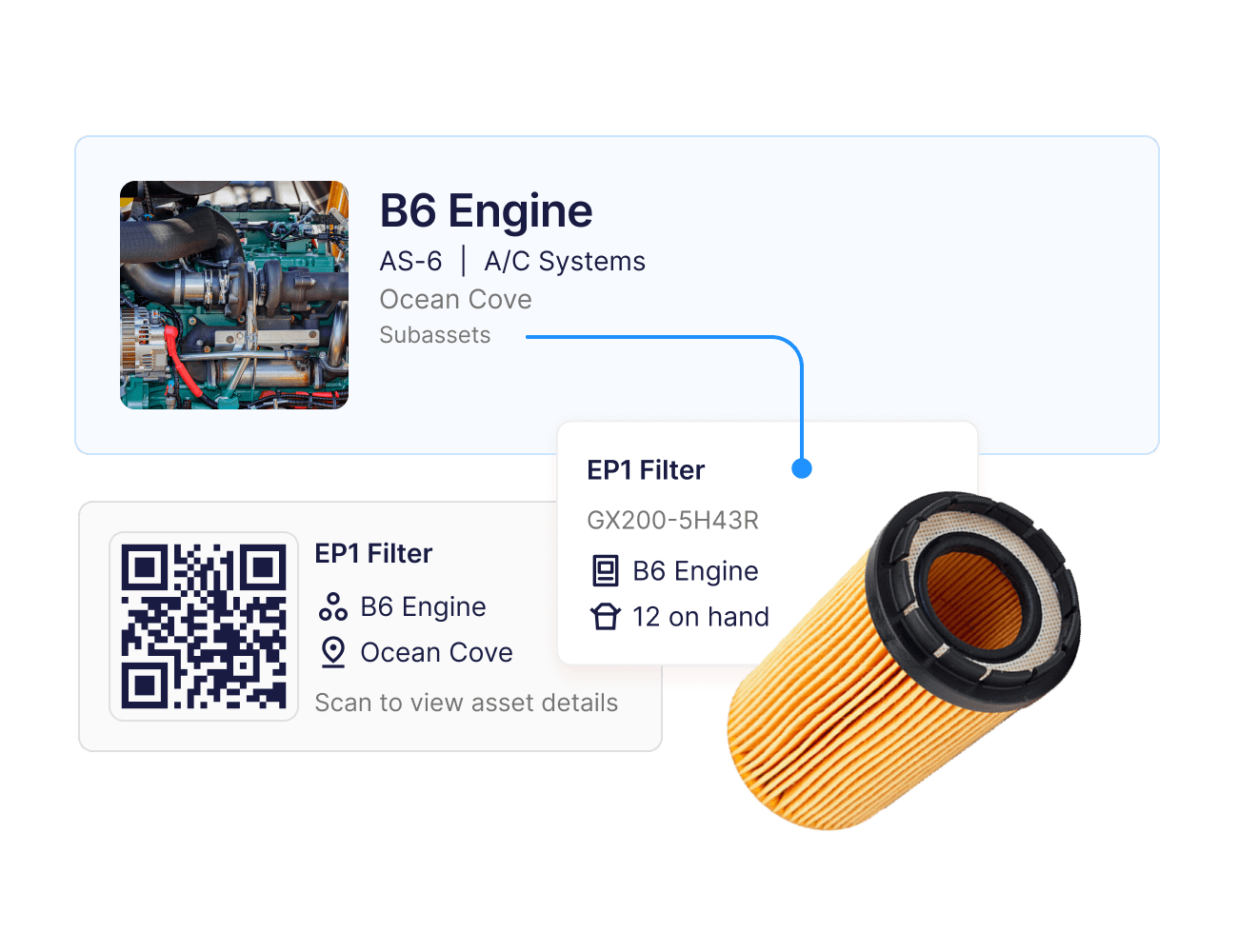

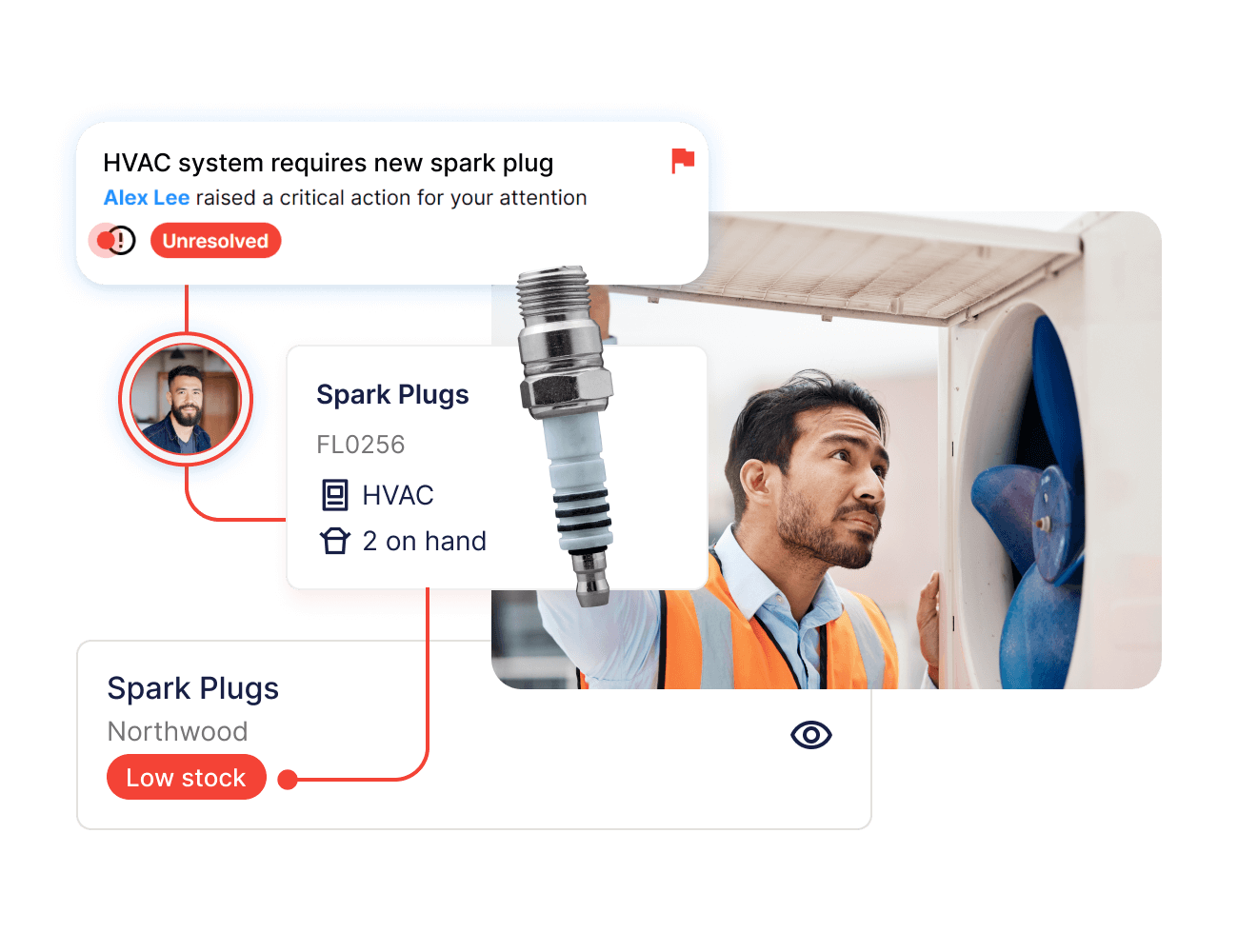

Operandio provides real-time inventory tracking for all parts and consumables. By setting low-stock alerts, your team receives automatic notifications the moment stock drops below minimum levels. This ensures replenishment happens before a shortage impacts your maintenance schedule or causes costly equipment downtime.

Trusted by thousands of multi-unit service businesses & franchise groups worldwide

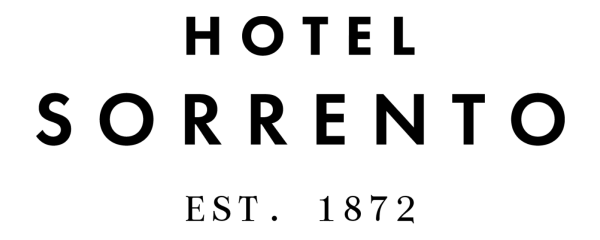

Track parts, consumables and stock levels

Monitor inventory levels across all sites. View quantity on hand, assigned items, usage trends and reorder status to avoid costly downtime.

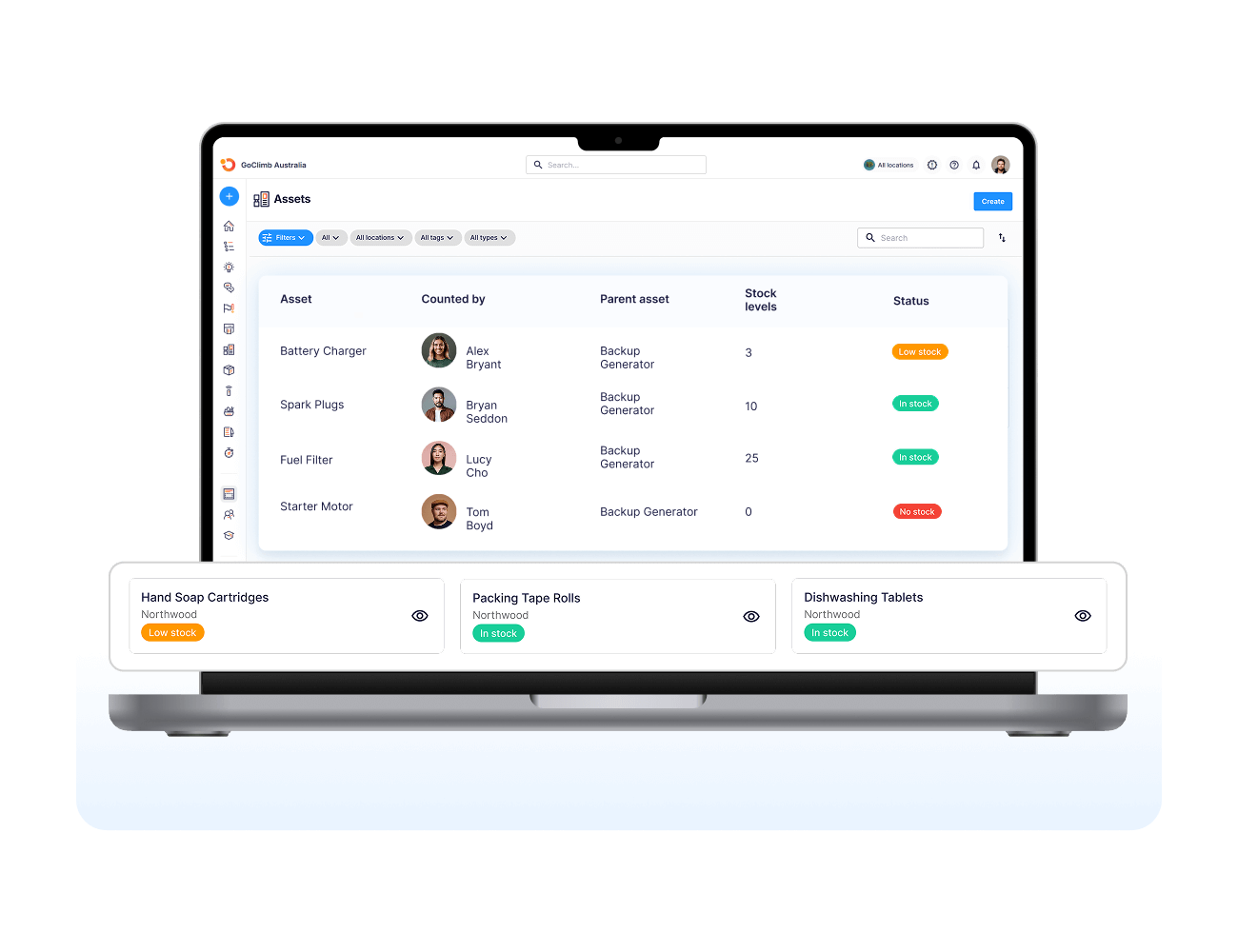

Link parts directly to assets and work orders

Assign parts and consumables to work orders or maintenance tasks. Track usage and cost per asset to understand repair expenses and asset performance.

Low-stock alerts and smarter replenishment

Receive automatic notifications when stock drops below minimum levels. Ensure parts are restocked before they impact maintenance schedules.

Transparent parts allocation

Track which work orders, assets or locations parts were assigned to, ensuring teams always know where inventory is being consumed.

Parts Inventory Mangement is just the start

Explore our full suite of Asset Management tools.

You’re in good company

Companies just like yours are using Operandio to achieve staff accountability, safety, compliance and consistent business processes across all their locations.

Frequently asked questions

Yes. You can link parts directly to assets and specific work orders. This allows you to track exactly which components were used for which repair, giving you a clear picture of the total cost of ownership and helping you identify assets that are becoming too expensive to maintain.

Absolutely. From a central dashboard, you can view quantity on hand and usage trends across your entire network. This visibility allows you to reallocate stock where it’s needed most and ensures that every site—regardless of location—has the necessary materials to keep repairs moving.

The platform provides transparent parts allocation, tracking exactly which work order, asset, or location a part was assigned to. This high level of accountability ensures your teams always know where inventory is being consumed, reducing waste and preventing inventory shrinkage.