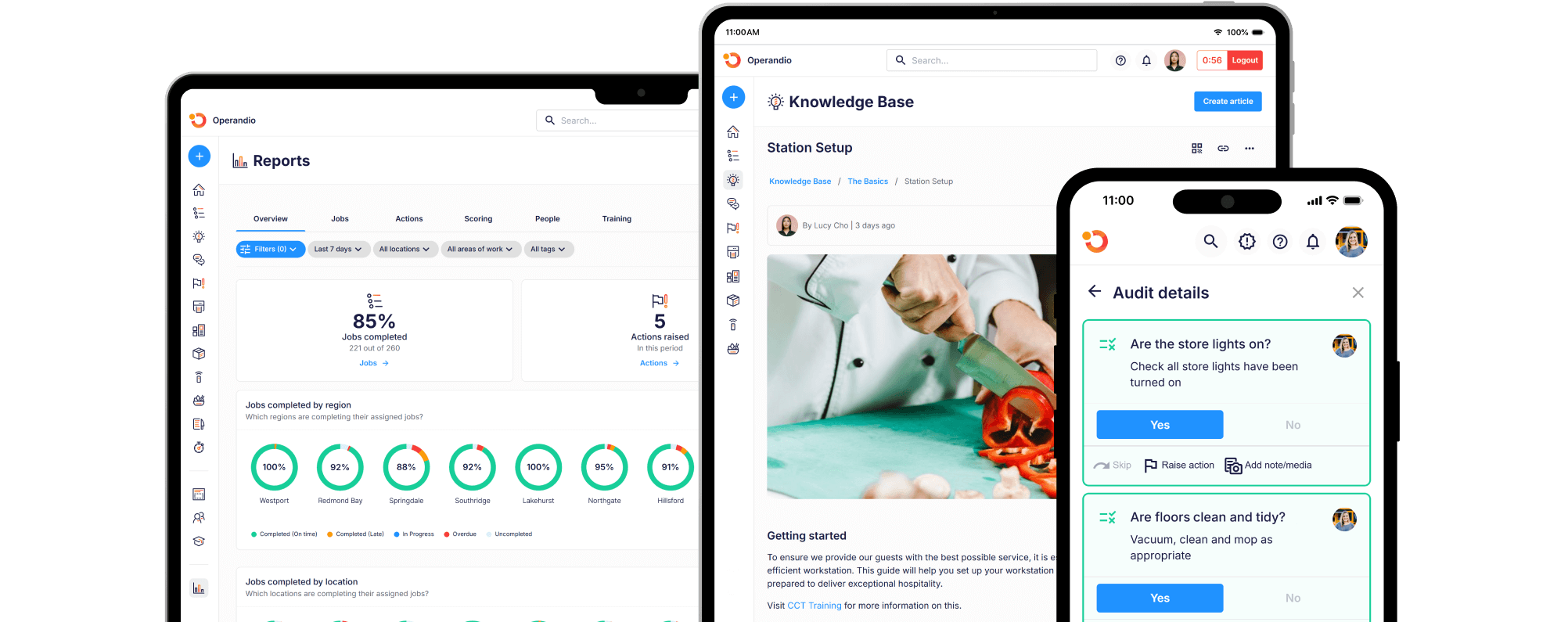

In seconds. Frontline teams can log issues immediately from their mobile device, attach photos of the problem, select the specific asset, and assign responsibility. This ensures that as soon as equipment fails or an inspection uncovers a fault, the right people are notified without delay.

Trusted by thousands of multi-unit service businesses & franchise groups worldwide

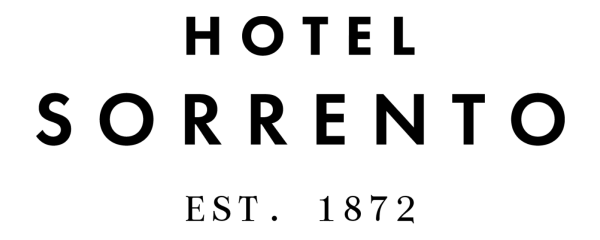

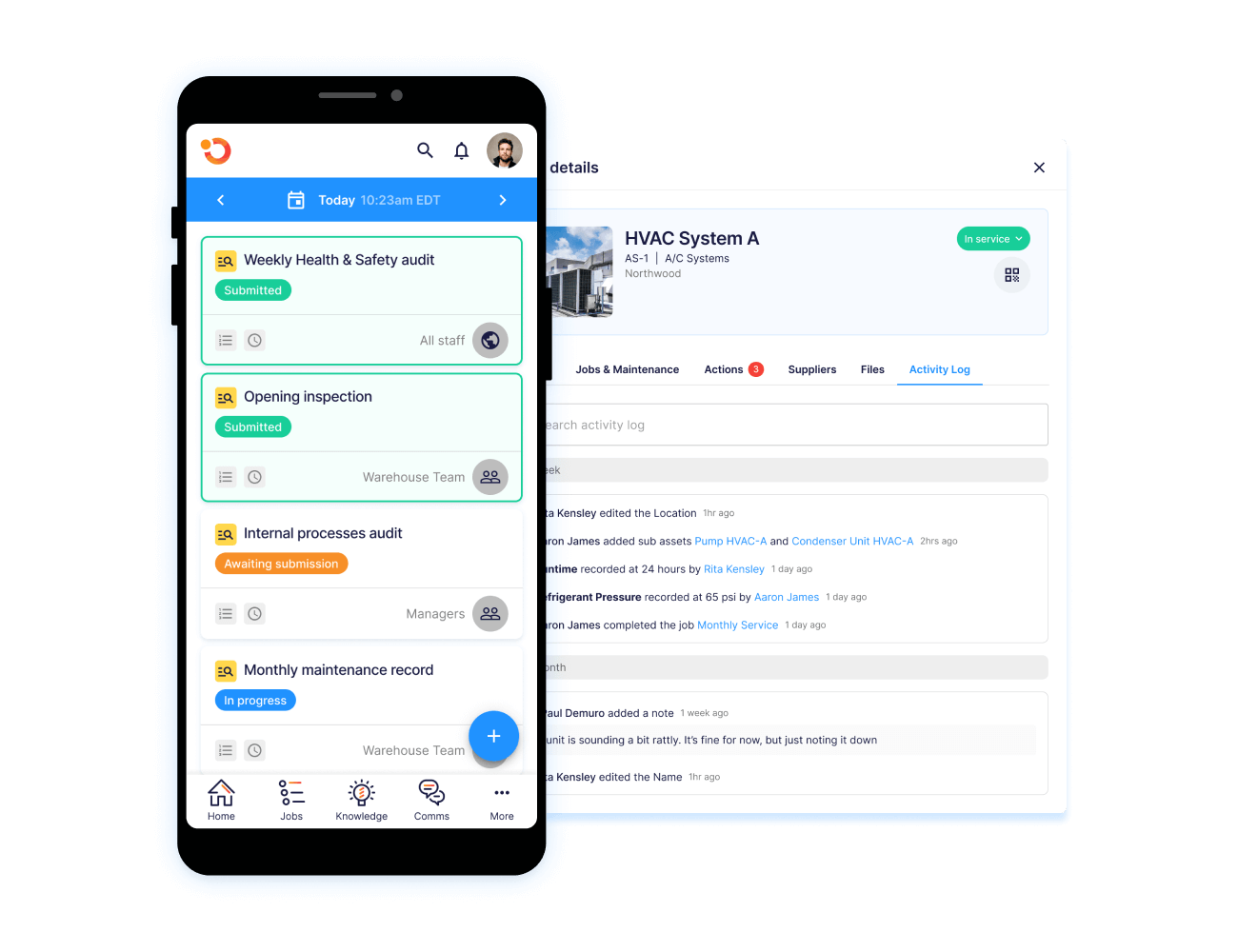

Create work orders in seconds

Log issues, attach photos, select the asset and assign responsibility. Frontline teams can raise work orders immediately when equipment fails or inspections uncover faults.

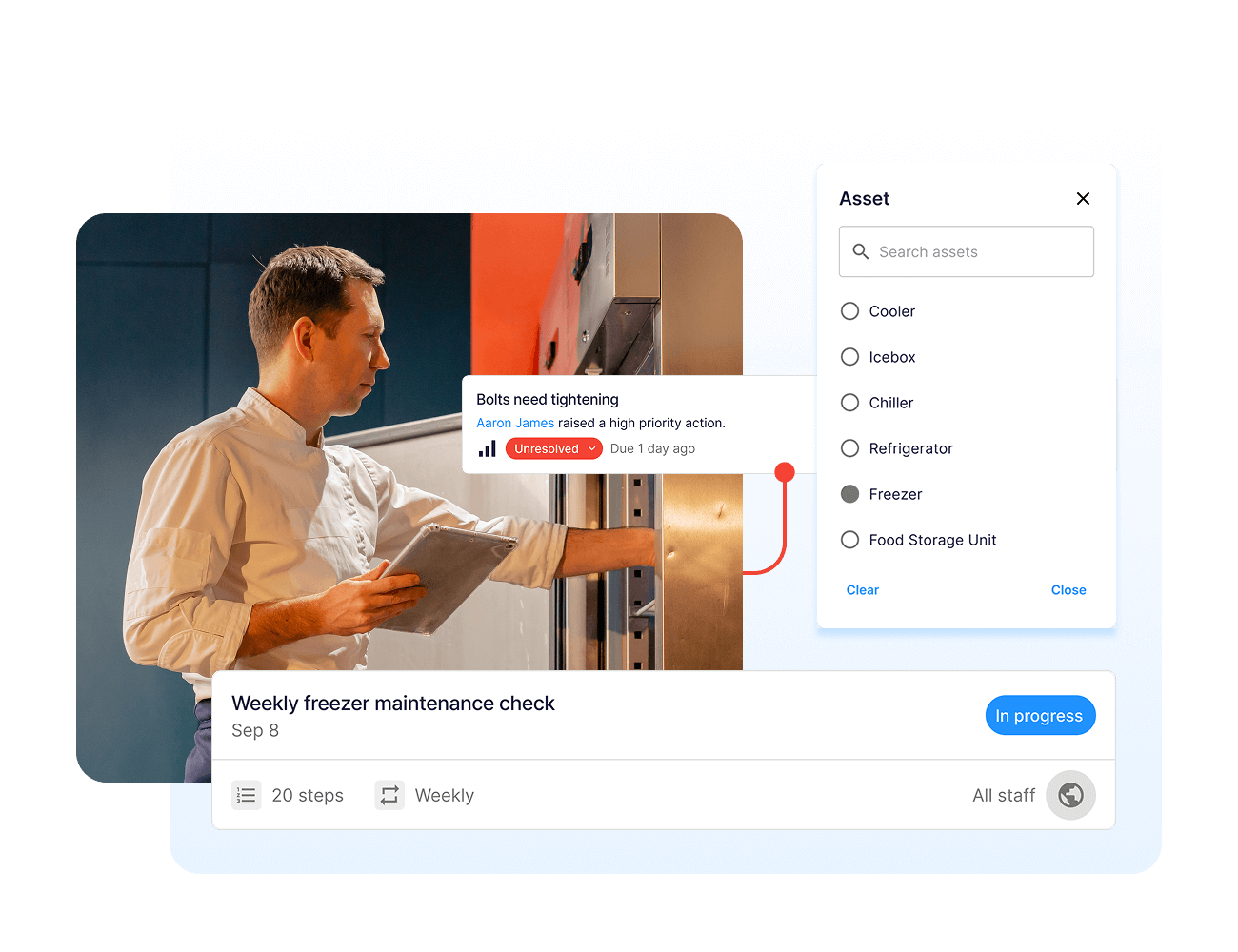

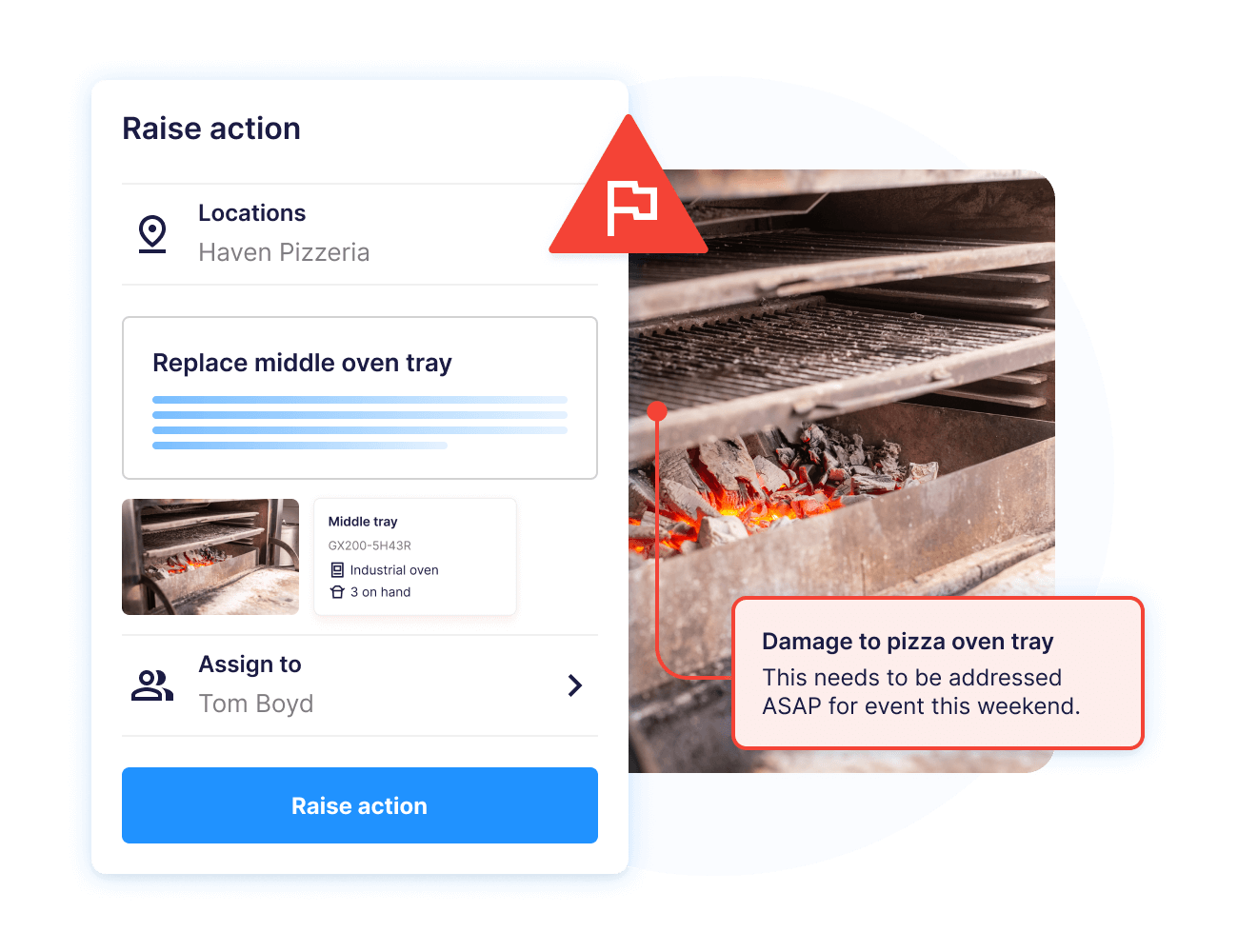

Assign tasks and track repairs to completion

Smart work orders automatically route tasks to the right people. Track progress, add notes, upload images and verify work completion with full accountability.

Integrated corrective actions and issue resolution

When inspections or incidents identify problems, corrective actions trigger work orders automatically. Ensure issues are repaired quickly and the entire process is fully documented.

Maintenance history and audit-ready records

Work orders, inspections, issues, photos and completion data are stored in a complete maintenance history. Perfect for audits, compliance and long-term performance analysis.

Smart Work Orders are just the start

Explore our full suite of Asset Management tools.

You’re in good company

Companies just like yours are using Operandio to achieve staff accountability, safety, compliance and consistent business processes across all their locations.

Frequently asked questions

Operandio uses smart work orders that automatically route tasks to the assigned person. Managers can track the repair from start to finish, view progress notes, and check uploaded images. The task isn’t marked as resolved until work completion is verified, ensuring full accountability at every site.

Yes. Through integrated corrective actions, work orders are triggered automatically when an inspection or safety incident identifies a problem. This bridges the gap between identifying an issue and fixing it, ensuring that every resolution is fully documented and nothing is overlooked.

Absolutely. Every work order, photo, and completion signature is stored in a complete maintenance history. These audit-ready records are perfect for proving compliance to inspectors and for performing long-term performance analysis to see which assets are recurring sources of downtime.