Food Safety Inspections: How to Completely Automate Inspections and Reduce Labour

Food safety inspections are a concept that you are going to become very familiar with if you decide to get into the restaurant industry – and for very good reason! It’s not about making sure your food tastes good. This is a matter of the health and safety of your patrons, and it is to be taken with utmost seriousness.

But, don’t worry. We’ve compiled this extensive guide to food safety inspections; from what they are, to how Operandio’s innovative software and hardware solutions can help you with all the food safety inspections you no doubt have coming your way.

What are food safety inspections?

Food Safety Inspections are Government procedures that are enacted to ensure that the food in an establishment is clean and safe for human consumption. This is because a lot of food preparation is conducted behind closed doors, so consumers are not able to gauge the safety of their food.

An inspection ensures that food products are not contaminated. Raw meat, for example, can be dangerous if it is not properly prepared. Additionally, harmful pathogens can spread quickly without proper cleaning and sanitising procedures. Essentially, Food Safety Inspections provide the council with an effective way of protecting consumers from food contamination and poor food handling practices.

What is the process of a food safety inspection?

Food Safety Inspectors, often called Environmental Health Officers (EHO’s), check that good food safety solutions are in place in important factors such as

- time and temperature control

- cleaning and sanitising

- personal hygiene of food handlers

When inspecting a food premises, EHO’s will often check that:

- Food is properly stored in clean, intact containers

- No raw meat comes into contact with other foods

- All foods are kept at proper temperatures

- Evidence of temperature checking in the form of a log is kept

- Cross contamination doesn’t occur by reusing food preparation tools and equipment

- Cleaning, sanitising and hand washing are done frequently and correctly

- All restaurant areas are clean

- Pest control precautions are in place

- Food labeling is accurate and sufficient

- A Food Safety Supervisor is on staff and reasonably contactable at all times

For a full list of what may be checked during an inspection, food businesses are advised to contact their local council.

How do I prepare for a food safety inspection?

There are many steps you should take to ensure that your restaurant is compliant with food safety regulations:

- Ensure that you have a designated and qualified Food Safety Supervisor

- Ensure that all relevant certification is easily accessible and ready for evaluation

- Issuing all staff with a Food Safety Card assists in making this process quick and easy.

- Look at your last hygiene and Food Safety Inspection report to check that you’ve taken all the actions needed to meet legal requirements

- Continue to make regular, routine checks to ensure hygiene standards are being maintained by all staff

- Check that staff are able to answer questions on food safety related to the food handling work they do

- Arrange for any repairs and conduct regular maintenance of the premises and equipment

For more insights on EcoSure Inspection, check out our detailed article.

And what can I do in between inspections to ensure my compliance with food safety regulations?

Don’t make the mistake of many businesses; failing to prepare! Food businesses often neglect these important steps:

- Cleaning and sanitising the food premises and equipment properly

- This includes cleaning and sanitising under, behind and inside equipment and appliances, and cleaning grease traps, floors and storage areas

- Ensuring that adequate hand-washing facilities are available and well-stocked at all times

- Controlling pest issues such as insects and mice, and implementing measures to ensure that infestations cannot take place on the premises

- Having a food temperature measuring device to keep high-risk food at the correct temperatures during both display and storage

- Covering food during storage and protect it from contamination

How does Operandio technology help maintain food safety?

Operandio inspection software optimises your standard operating procedures to ensure that they best meet food safety regulations:

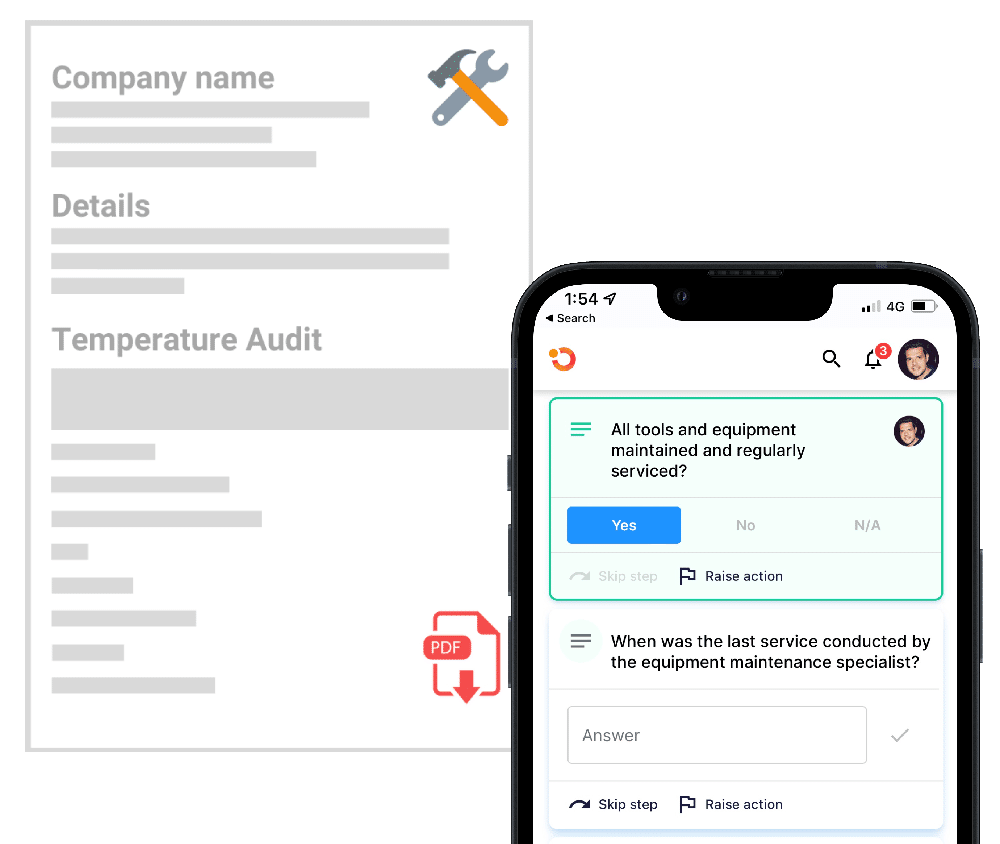

SOP Automation Checklist Software

Checklist software is important for food safety if you want your patients to have the best standard of care possible. Operandio’s management software automates food safety monitoring that your staff don’t need to worry about, giving them the time to focus their efforts on tending to your customers.

With Operandio checklist software, you can:

- Create checklists and tasks for the processes specific to your business, whether they’re recurring or ad hoc.

- Make accountability a priority. Meet deadlines and ensure tasks are completed according to standard.

- Delegate jobs to individuals, teams, divisions or an entire branch.

- Easily update processes as they change and keep your staff informed, even across multiple locations.

Automated Temperature Monitoring

Automated food temperature monitoring for restaurants is crucial to ensure their longevity. Monitoring and regulating temperature plays an important role in the storage of food, which means you can’t afford to implement half measures.

That is why Operandio offers temperature sensor technology that is efficient, easy-to-use and that allows you to:

- Get instant, accurate and detailed temperature readings in real time

- Receive SMS and email alerts whenever there is a potentially dangerous temperature change

- Monitor multiple places at once; including display fridges, industrial fridges and freezers, and even server rooms

- Observe changes in temperature and relative humidity over an extended period of time

Book your demo with Operandio today, and take control of your business.