What are Food Contact Surfaces and How to Keep Them Clean

Key Takeaways

- Food contact surfaces include any item that comes into contact with food, such as hands, utensils, equipment, containers, and prep counters. If they aren’t cleaned properly, they can spread bacteria and allergens.

- Cleaning and sanitizing are different steps. Cleaning removes food residue. Sanitizing kills bacteria. Both are required.

- Surfaces must be cleaned at the correct times, including after each task, between raw and ready-to-eat foods, every four hours during use, after contamination, and before each shift.

- Consistency is the hardest part. Busy shifts and manual logs lead to missed steps. Clear procedures and simple task tracking help teams stay compliant.

Ever realized a kitchen surface wasn’t adequately cleaned before food prep? It happens more often than people admit.

Food contact surfaces include any item that comes into contact with food during preparation, cooking, storage, or service. If they aren’t cleaned and sanitized correctly, bacteria can spread quickly and put customers at risk.

This guide explains what food contact surfaces are, where contamination usually happens, and how to keep them clean and safe every day.

What is a Food Contact Surface?

A food contact surface is anything that directly touches food during preparation, cooking, storage, or service, including countertops, cutting boards, utensils, containers, equipment, and even hands.

Surfaces can look clean but still harbor pathogens. Without proper sanitation, bacteria multiply rapidly, causing foodborne illnesses.

So, always make sure anything coming into contact with your food meets safety standards and is appropriately maintained. Also, clean after every use.

The FDA regulates these under food contact substance guidelines, defining them as materials used in manufacturing, packing, packaging, transporting, or holding food.

What are the Different Types of Food Contact Surfaces?

Each surface type presents different contamination risks and cleaning requirements.

- Hands: Your hands have the highest-risk contact surface. Contamination occurs through touching raw proteins, unwashed produce, contaminated equipment, restrooms, or trash. Without frequent handwashing, bacteria can transfer directly to ready-to-eat foods, causing outbreaks.

- Clothing and gloves: Aprons and uniforms collect food particles and bacteria throughout shifts. Contamination happens when staff touch raw foods and then ready-to-eat items without changing gloves, or when dirty aprons brush clean prep surfaces. Gloves create a false sense of security; they protect hands, but can transfer bacteria if not changed between tasks.

- Food containers: Oftentimes, storage containers, serving dishes, and transport vessels accumulate bacteria in cracks, seals, and corners. Contamination occurs when containers aren’t cleaned between uses or when the same container holds different foods without washing. And Damaged containers with cracks harbor bacteria that even washing can’t remove.

- Utensils and equipment: Kitchen equipment like knives, cutting boards, mixers, slicers, and cookware come into contact with multiple types of food throughout service. Inadequate cleaning between uses, especially when switching from raw to cooked foods, spreads contamination. Complex equipment like meat slicers creates hard-to-clean areas where bacteria accumulate. Wooden boards absorb liquids and develop cuts that trap pathogens.

- Workstations and counters: Prep surfaces are in constant contact with a wide range of ingredients. So Contamination occurs when surfaces aren’t cleaned between food types, when raw juices spread, or when cleaning cloths redistribute bacteria instead of removing them. Also, porous materials absorb liquids and bacteria; scratched surfaces create hiding spots for pathogens.

Importance of Keeping Food Contact Surfaces Clean

Clean surfaces are the foundation of food industry compliance.

One common reason for keeping food contact surfaces clean is to prevent the widespread of diseases.

Bacteria spread fast. A typical example is the Salmonella bacteria, which doubles every 20 minutes at room temperature.

So the cross-contamination between raw and ready-to-eat foods is particularly dangerous because it introduces pathogens to foods that won’t be cooked before service.

But clean surfaces also prevent pest problems by eliminating food residue that attracts insects and rodents.

Compliance management requires documented schedules, proper sanitizer use, and staff training to prove you maintain standards consistently.

How to Clean and Sanitize a Food Contact Surface

The combo method for keeping a clean food surface environment is to clean and sanitize.

Cleaning removes visible dirt, while sanitizing kills bacteria. See more details below on how to get this done:

| Step | What to Do | Why It Matters |

| Remove debris | Scrape food particles, grease, and spills | Prevents buildup that harbors bacteria |

| Wash | Scrub with hot, soapy water | Removes grease, dirt, and contaminants |

| Rinse | Use clean water to remove soap | Detergent interferes with sanitizer |

| Sanitize | Apply food-safe sanitizer | Kills bacteria and pathogens |

| Contact time | Let it sit for 30 seconds to 1 minute | Gives sanitizer time to work |

| Air dry | Let dry or use a clean towel | Avoids recontamination |

1. Remove Food Debris and Residue

Scrape off visible food particles, grease, and spills with a clean scraper or disposable towel. Organic matter blocks sanitizer from reaching surfaces, creating protected areas where bacteria survive.

Disassemble equipment with moving parts before cleaning to ensure all contact surfaces are reached.

2. Wash with Hot Soapy Water

Use hot water and detergents designed for food-contact surfaces. Always scrub with a clean cloth, brush, or non-abrasive pad.

Friction physically removes bacteria that soap alone can’t eliminate. For textured surfaces, use brushes that reach into grooves.

Pro Tip: Keep separate tools for raw protein areas and ready-to-eat zones. Color-coded brushes prevent cross-contamination during cleaning.

3. Rinse Thoroughly

Rinse all surfaces with clean water to remove soap residue. Leftover detergent interferes with sanitizer contact and can contaminate food. For complex equipment, use spray nozzles to flush soap from hard-to-reach areas.

4. Apply Food-Safe Sanitizer

Use EPA-registered, food-safe sanitizer at proper concentration:

- Chlorine (bleach): 50-100 ppm. Mix 1 tablespoon of unscented bleach per gallon of water. Effective but corrodes some metals.

- Quaternary ammonium (quats): 200-400 ppm. Longer-lasting, less corrosive, but bacteria can develop resistance.

- Iodine: 12.5-25 ppm. Effective but stains porous surfaces and costs more.

Apply with spray bottles. Test the sanitizers before use with a test strip. If it’s too weak, it won’t kill bacteria. And if it’s too strong, it may become a chemical hazard. So the sweet spot remains in the middle.

5. Allow Proper Contact Time

Let sanitizer remain on the surface for 30 seconds to 1 minute. Don’t wipe immediately because bacteria need contact time to die. Surfaces should stay visibly wet during this period.

6. Air Dry

Air dry whenever possible to prevent recontamination from dirty towels. If you must dry manually, use single-use paper towels or clean cloths changed frequently.

Never use the same cloth for multiple surfaces. Following proper restaurant cleaning procedures ensures that every step is performed correctly.

When Should Food Contact Surfaces Be Cleaned and Sanitized?

Your food contact surfaces should be cleaned periodically before nd after use. But that’s not all, let’s see this in more detail:

After Each Use or Task

Clean immediately after preparing raw proteins, cutting produce, or completing any prep task. A cutting board used for raw chicken must be thoroughly cleaned before cutting vegetables — even 30 seconds allows bacteria transfer.

Between Different Food Types

Switching from raw to cooked foods or between allergen categories requires immediate cleaning. Cross-contamination happens in seconds.

Front-of-house templates help servers maintain customer-facing surfaces, while back-of-house protocols keep kitchen surfaces safe.

Every Four Hours During Continuous Use

Surfaces in continuous use for the same food type still need to be cleaned every 4 hours, minimum. Bacteria multiply on surfaces that appear clean. Set timers, don’t rely on visual assessment.

Any Time Contamination Occurs

Spills, dropped items, or suspected contamination require immediate cleaning. This includes phones on prep counters, keys on cutting boards, or cloths that have touched the floor.

Maintaining kitchen hygiene means staff clean proactively, not just on schedule.

Before Starting Each Shift

Surfaces cleaned at the end of the previous shift need re-sanitizing before use. Overnight bacteria growth, dust, or pest activity can contaminate surfaces.

Avoiding common food safety mistakes starts with consistent routines.

Common Mistakes in Food Contact Surface Hygiene

Here are the common mistakes you should watch out for in your commercial kitchens.

- Sanitizing dirty surfaces: Organic matter blocks sanitizer from reaching bacteria. Always clean first.

- Wrong sanitizer concentration: Too weak won’t kill bacteria; too strong creates chemical hazards. Use test strips every time.

- Inadequate contact time: Wiping sanitizer off immediately doesn’t work. Surfaces need 30-60 seconds of wet contact time.

- Same cloth for multiple surfaces: Cloths spread bacteria instead of removing it. Change frequently or use single-use towels.

- Skipping equipment disassembly: Hidden areas accumulate bacteria. Disassemble before cleaning.

- Ignoring high-touch areas: Handles, knobs, switches transfer bacteria between hands and food surfaces.

- Not replacing worn surfaces: Deep scratches and cracks harbor bacteria that cleaning can’t reach. Replace damaged items regularly.

- Inconsistent schedules: Time-based protocols prevent gaps that allow bacteria to multiply. Clean every four hours regardless of appearance.

- Poor documentation: Digital systems timestamp completion and prevent backdated records that paper logs allow.

Best Practices for Maintaining Food Contact Surfaces

1. Clean and Sanitize Regularly

Establish time-based schedules, not visual assessment. Surfaces in continuous use need attention every four hours.

Use weekly cleaning schedules and commercial kitchen checklists that assign specific tasks to specific times.

2. Use the Right Cleaning Products

Match products to surface materials. Food-safe sanitizers must be EPA-registered.

Never substitute household cleaners containing chemicals unsafe for food contact. Store cleaning chemicals away from prep areas and keep Safety Data Sheets accessible.

3. Separate Cleaning Tools for Food and Non-Food Areas

Color-coded systems prevent cross-contamination during cleaning:

- Green for produce.

- Red for raw proteins.

- Yellow for ready-to-eat foods

- And blue for general cleaning.

Store tools away from food prep areas.

4. Scrub Thoroughly, Don’t Just Wipe

Use brushes and abrasive pads appropriate for each material. Friction physically removes bacteria that chemicals can’t eliminate. Disassemble complex equipment completely; bacteria hide where you can’t see.

5. Monitor Cleanliness with Inspections

Food safety inspections using ATP testing or swab tests detect invisible contamination. Digital task management systems track completion and flag missed tasks in real time.

Building a strong food safety culture means your staff understand why cleaning matters.

It’s clear, when you prioritizes hygiene over speed during rushes, standards become non-negotiable.

6. Replace Damaged or Worn-Out Surfaces

Inspect daily for kitchen utensil marks, cracks, chips, or discoloration.

Set replacement schedules based on usage intensity.

Pro Tip: Non-porous materials like stainless steel resist bacteria and withstand repeated sanitizer exposure better than wood or soft plastics.

Monitor and Maintain Restaurant Hygiene with Operandio

Most kitchens don’t struggle with knowing what to clean. They struggle to ensure it actually gets done on every shift.

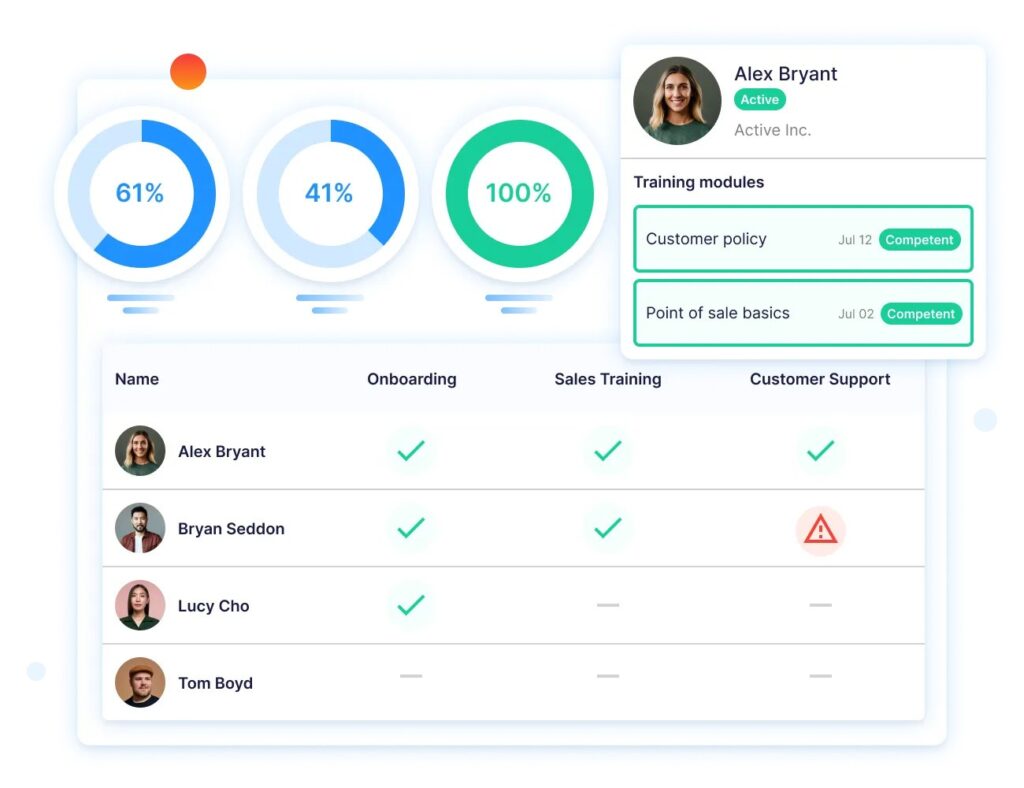

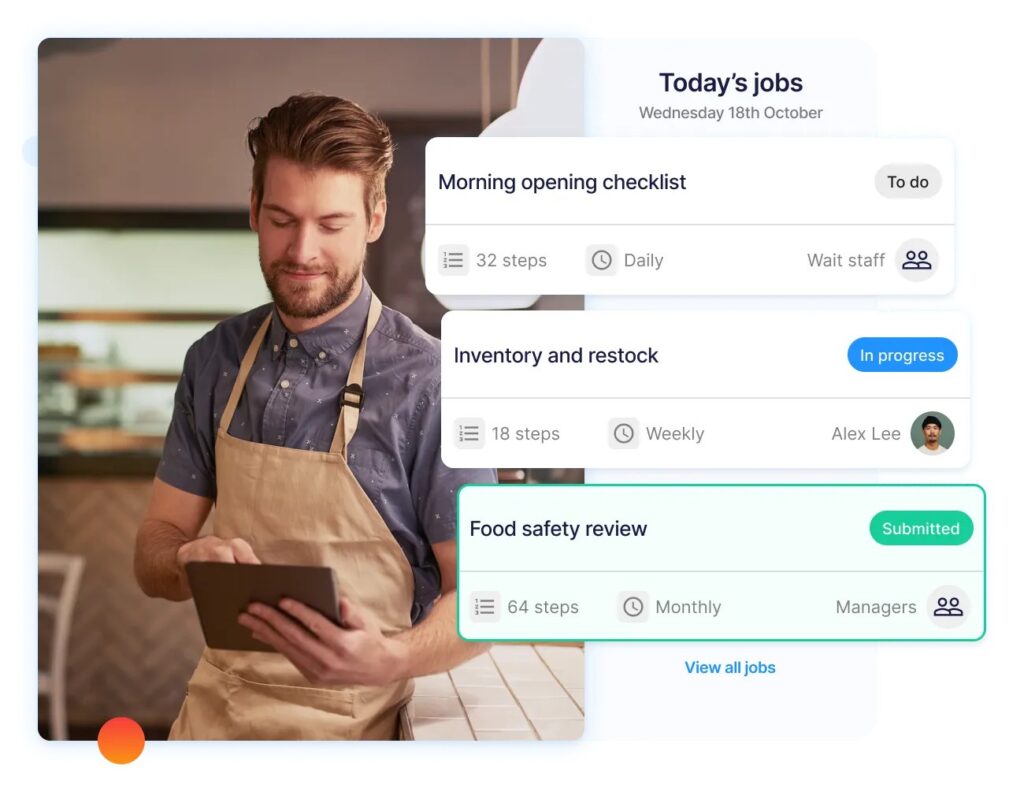

Operandio helps by turning surface hygiene into part of daily work. Cleaning tasks are scheduled, assigned by role, and tracked in real time on the task management section.

So staff know exactly what to clean and when.

Managers can verify completion through timestamped records rather than walking the floor or guessing. If something’s missed, it’s obvious right away, not during an inspection.

Request a demo and see how digital systems make food contact surface hygiene consistent, verifiable, and inspection-ready.