What is a Food Safety Plan and How to Build One [2026 Guide]

Key Takeaways

- A food safety plan documents how you identify and control food safety risks during your shift. Most FDA-registered facilities must have one, and every restaurant benefits from it.

- A food safety plan may be built in four steps: confirm requirements, identify hazards, set clear control limits, and define what to do when something goes wrong.

- A strong plan includes hazard records, clear monitoring steps, and corrective actions your team can follow during real service, not ideal conditions.

- Most plans fail because of turnover, rush periods, and outdated docs. Digital systems, like Operandio, address this by making compliance part of daily work.

Food safety failures rarely come from evil intent. They come from gaps no one saw in time.

In 2024, foodborne illness cases linked to recalls rose sharply. The issue was a lack of clear, documented systems that prevented problems from being caught early.

So creating a food safety plan for your restaurant can’t be overlooked.

This guide explains what a food safety plan is, who needs one, and how to build a version that holds up during Friday night rush.

What is a Food Safety Plan?

A food safety plan documents how you identify and control hazards throughout your restaurant operations.

Think of it as your operational playbook for food safety culture. It specifies what you monitor, when you monitor it, and what happens when something goes wrong.

Most FDA-registered facilities must have one under the Food Safety Modernization Act. State health departments often require it even for exempt operations.

More importantly, with a proper food safety plan, you can catch problems before they become outbreaks, which helps you avoid common food safety mistakes that close restaurants.

How to Create a Food Safety Plan: Step-by-Step Process

Build your plan through these four essential steps.

Step 1: Confirm Requirements and Assemble Your Team

Check what regulations apply: federal (FDA Food Code), state adaptations, and local ordinances. Your health department tells you what’s mandatory, some facilities need a Preventive Controls Qualified Individual (PCQI), others use HACCP-trained personnel.

And then assemble a team from experienced employees in your restaurant: someone who knows the menu (chef or kitchen manager), someone familiar with regulations, and input from line staff who execute procedures during service.

Step 2: Conduct Hazard Analysis

Your restaurant risk assessment should focus on controls where they matter most.

Common restaurant hazards:

- Allergen cross-contact.

- Poor employee hygiene.

- Temperature abuse during storage and cooling.

- Undercooking high-risk items (poultry, ground beef).

- Cross-contamination between raw and ready-to-eat foods.

Step 3: Set Control Points and Limits

Use specific targets like cooking temperatures, cooling times, and holding thresholds.

And decide who checks, when, and how. Your food safety monitoring should make compliance routine, not optional.

The designated employee for Identifying Critical Control Points (CCPs) should take note of the following:

- Cooking: 165°F for poultry, 145°F for whole beef, 155°F for ground meats.

- Cooling: 135°F to 70°F within 2 hours, then 70°F to 41°F within 4 hours.

- Cold holding: 41°F or below.

- Hot holding: 135°F or above.

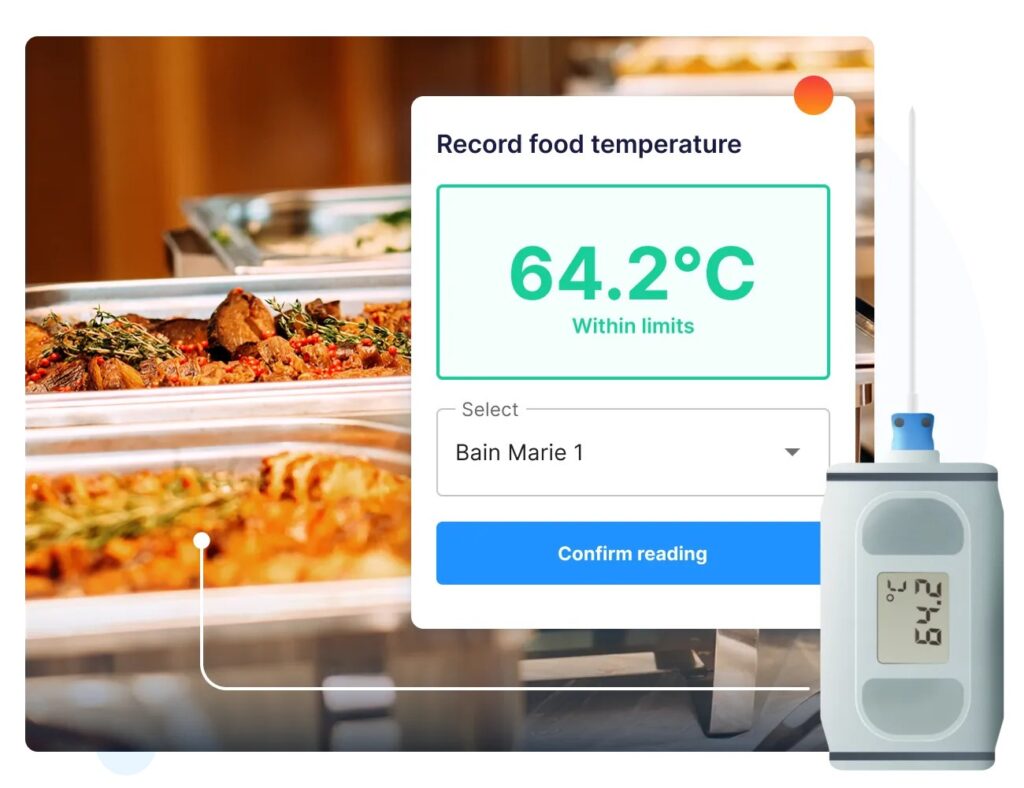

Operandio’s temperature sensor monitoring removes that risk. Sensors track temperatures continuously and alert managers the moment readings fall outside safe ranges, so teams catch issues early without relying on memory or paper logs.

Step 4: Document Procedures and Corrective Actions

Write procedures in simple language: “Check walk-in temp at open, mid-shift, close. Record on log. If temp exceeds 41°F, notify manager and move products to backup cooler.”

For each CCP, document corrective actions:

- Prevention (stop recurrence).

- Product evaluation (is food safe?).

- Root cause (why did this happen?).

- Immediate correction (fix the problem now).

Keep records for two years. Use food safety record templates to maintain standard documentation.

Train staff on procedures through developing an effective food safety plan that integrates with restaurant onboarding.

Key Components of a Food Safety Plan

Every complete plan includes these core elements.

#1: Hazard Analysis Documentation

List every biological, chemical, and physical hazard in your operation. Note how likely each is, how severe it would be, and whether it needs a control.

Common risks include pathogens like Salmonella and E. coli, allergen cross-contact, cleaning residue, and physical debris such as metal or glass.

Your analysis should reflect your actual menu and processes, not generic templates. This forms the basis for your health and safety guidelines for restaurants.

#2: Preventive Controls and Monitoring Procedures

Specify the measures that control identified hazards:

- Process controls: Cooking, cooling, acidification.

- Supply chain controls: Supplier verification for ready-to-eat items.

- Allergen controls: Separate storage, dedicated equipment, clean-between protocols.

- Sanitation controls: Cleaning of food-contact surfaces and prevention of cross-contamination.

For each control, document parameters (temperature, time), monitoring frequency, responsible person, and deviation criteria.

#3: Corrective Actions and Verification

Schedule verification activities: calibrate equipment weekly, audit procedures monthly using your restaurant cleaning checklist template, and review the whole plan annually.

Build these into restaurant training programs to ensure consistency.

Also keep records for two years per legal requirements for restaurant staff training compliance.

Benefits of a Food Safety Plan

Beyond compliance, documented plans deliver real operational advantages.

Prevents Costly Outbreaks and Violations

Imagine if you identify the cooler malfunction at 7 am instead of during lunch rush. Critical violations that shut operations down cost $5,000- $15,000 in daily lost revenue.

Digital food safety software provides timestamped, unalterable proof that helps you avoid violations entirely.

Streamlines Health Inspections

Can you produce today’s temp log and manager certification in 30 seconds? That’s what inspectors expect.

So a restaurant with a well documented food safety plan have a higher chance to score high on food safety inspections. You’re not scrambling to explain gaps, everything is written and accessible.

Improves Multi-Location Consistency

Single locations rely on personal oversight. Multi-unit operations need documented systems through restaurant management software.

Your plan becomes the standard across sites. Each location follows identical controls, uses the same limits, and documents consistently. You catch compliance issues before inspections reveal them.

Protects Brand Reputation and Reduces Insurance Costs

One social media complaint about illness can destroy several months of reputation work your restaurant have built.

But your documented plan demonstrates a commitment to customer welfare and helps maintain compliance with the food safety certificate.

Some insurance carriers offer 10-15% premium reductions for restaurants with documented food safety culture through strong food industry compliance management. The savings often cover annual plan maintenance.

Difference Between a HACCP Plan and a Food Safety Plan

These terms often get mixed up, but they serve different roles. HACCP follows seven defined principles to control hazards at critical points and is required for seafood, juice, meat, and poultry operations.

Food safety plans under FSMA build on HACCP and cover a wider scope. They address more hazard types and require controls for processes, allergens, sanitation, and suppliers.

In practice, HACCP relies on strict numeric limits, like cooking temperatures. Food safety plans use both numbers and visual or procedural checks to prove controls work on shift.

Most restaurants need HACCP rather than full FSMA preventive controls. Your HACCP plan can become part of a broader food safety plan. Check with your health department to confirm requirements for your operation.

| Feature | HACCP Plan | Food Safety Plan (FSMA) |

| Focus | Critical Control Points | Preventive Controls (broader) |

| Controls | Process at CCPs | Process, Allergen, Sanitation, Supply Chain |

| Limits | Quantifiable only | Quantifiable + Qualitative |

| Developer | HACCP-trained personnel | PCQI required |

| Required For | Seafood, juice, meat, poultry | Most FDA-registered facilities |

Whether you need HACCP management software or broader food safety tools depends on your regulatory requirements.

You can compare free and paid HACCP software solutions based on your operation’s complexity and regulatory scope.

Challenges to Creating a Food Safety Plan

Implementation breaks down at these critical points.

Challenge #1: Staff Turnover Disrupts Trained Procedures

Restaurants average 70-80% annual turnover. You train staff and establish compliance, only to have half your team be new three months later.

Food safety gets abbreviated during rushed onboarding when you need bodies on the line. Procedures don’t get followed because new staff don’t know they exist.

The fix: Build food safety into role-specific onboarding through restaurant training software. And use restaurant safety training modules for consistency.

Brief daily safety huddles work better than quarterly marathons. Five-minute check-ins beat hour-long meetings that half the team misses.

Challenge #2: Peak Service Breaks Compliance

Your plan works on paper. Then Friday hits, 45 minutes behind, three servers out. Nobody checks hold temps. Logs get “caught up” at closing.

This execution gap kills most plans. They’re designed for ideal conditions, not operational chaos.

The fix: Design procedures that work during rush. If two-hour temp checks are unrealistic during peak service, use continuous monitoring with automated alerts. Make compliance passive—IoT sensors monitor automatically, photo-verified tasks take 10 seconds.

Operandio’s compliance software assigns role-specific responsibilities and sends real-time alerts when tasks are overdue. Staff check procedures from phones with photo verification, creating automatic documentation without slowing service.

Challenge #3: Documentation Gets Outdated or Lost

Manual logs fail in two ways: staff fill them in after the fact or lose them entirely. Inspectors catch this fast through identical handwriting or “perfect” temperatures.

Start with high-risk records like temperature checks and corrective actions. Digitize those first. Whatever system you use, you should be able to pull critical records in 30 seconds during an inspection.

Implement food traceability systems that connect documentation across receiving, storage, prep, and service for complete visibility.

Stay on Top of Food Safety Compliance with Operandio

A food safety plan only works when teams follow it on shift. Most failures happen between written rules and real-world execution, especially during busy service.

Operandio closes that gap. Tasks trigger on time, proof captures automatically, and alerts surface issues before they turn into violations.

Whether you run one location or many, Operandio gives you clear visibility and control across every shift. Your plan becomes part of daily work, not a binder on a shelf.

Ready to move from documentation to execution? Request a demo to see how Operandio supports consistent food safety across every location.